TM 5-3805-290-23-1

TRANSMISSION TESTS, INSPECTIONS, AND ADJUSTMENTS - CONTINUED

0014 00

TRANSMISSION CONTROL (SHIFT LEVER) TEST - CONTINUED

9.

Check shifter harness and ECM.

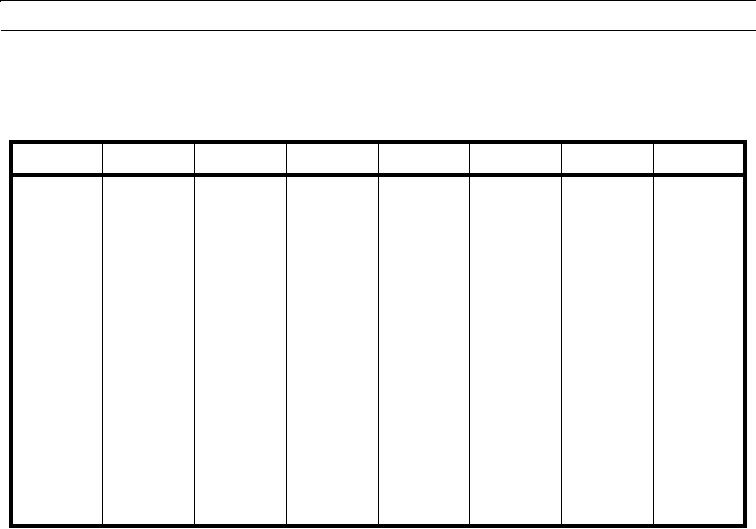

Table 3. Valid Shift Lever Input Status.

Output

Forward

Neutral

Reverse

First Gear

Second Gear

Third Gear

Fourth Gear

1F

X

O

O

X

O

O

O

2F

X

O

O

O

X

O

O

3F

X

O

O

O

O

X

O

4F

X

O

O

O

O

O

X

1N

O

X

O

X

O

O

O

2N

O

X

O

O

X

O

O

3N

O

X

O

O

O

X

O

4N

O

X

O

O

O

O

X

1R

O

O

X

X

O

O

O

2R

O

O

X

O

X

O

O

3R

O

O

X

O

O

X

O

4R

O

O

X

O

O

O

X

N

O

X

O

O

O

O

O

a.

Shift lever has three connectors:

(1)

8-Pin Connector

(2)

6-Pin Connector

(3)

4-Pin Connector

b.

At shifter, disconnect 8-pin harness connector CN-C52 (WP 0081 00). 6-pin harness connector remains connected

to shifter 6-pin connector. Shifter 4-pin connector remains connected between pins 3 and 4.

c.

Refer to shifter schematic and connect two jumper wires from shifter connectors to frame ground to simulate each

position of shifter. If particular position is already suspect, begin with wires for that position.

d.

Monitor status of shifter on MSD screen.

e.

Expected Results. As each combination of contacts is grounded, MSD screen displays corresponding shifter posi-

tion.

(1)

If results are OK, ECM and wiring harness appear to be working correctly. Replace shifter (WP 0081 00).

(2)

If results are NOT OK, wiring harness or ECM is not working correctly. Proceed to step 11.

0014 00-14