TM 5-3805-290-23-2

PRIMING FUEL SYSTEM - CONTINUED

0029 00

PRIMING FUEL SYSTEM

1.

Turn battery disconnect switch to ON position (TM 5-3805-290-10).

2.

Turn engine start switch to ON position (TM 5-3805-290-10) for 60 seconds to operate fuel priming pump (3).

3.

Start and run engine for minimum of 5 minutes (TM 5-3805-290-10).

4.

If engine does not start, repeat steps 1 thru 3. If on second attempt, engine does not start, perform steps 5 thru 9.

CAU T I ON

Running engine for at least five minutes will help ensure that pump is completely free of air. It will also pre-

vent damage to internal parts of pump caused by metal-to-metal contact. If engine stops or runs roughly,

check for air in fuel system. If air is in fuel system, leakage in low pressure fuel system probably exists.

Damage to fuel injection pump, battery, and starter motor can occur if starter motor is used excessively to

purge air from fuel system.

Utilize two line wrenches to avoid damage to fittings.

N OT E

If engine does not run satisfactorily or will not start after two attempts of priming have been made, perform

steps 5 thru 9.

5.

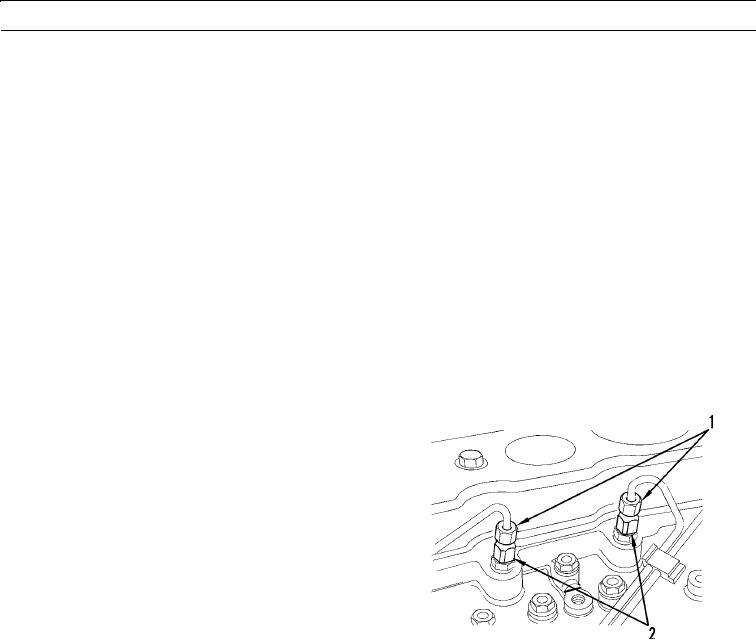

Loosen two flare nuts (1) for high pressure fuel lines

on two fuel injection nozzles (2).

N OT E

DO NOT crank starter motor continu-

ously for more than 30 seconds. Allow

starter motor to cool for two minutes

before cranking engine again.

6.

Operate starter motor until fuel is flowing from fuel

lines (TM 5-3805-290-10).

427-B0276

CAU T I ON

Engine will start and run during cranking operation. Be aware of all moving parts during this procedure.

7.

Run engine until fuel from injector lines appears free of bubbles.

8.

Tighten flare nuts (1) to 16 lb-ft (22 Nm).

9.

Operate engine at low idle for a minimum of five minutes immediately after air has been removed from fuel system.

WAR N I N G

Before operating equipment, secure the steering frame lock in the stowed position. DO NOT operate

machine with steering frame lock connected. Failure to lock steering frame lock into the stowed position

before operating can result in loss of steering and injury or death to personnel.

10.

Secure steering frame lock in stowed position (TM 5-3805-290-10).

END OF WORK PACKAGE

0029 00-2