TM 5-3805-290-23-2

FLYWHEEL HOUSING REPLACEMENT - CONTINUED

0151 00

INSTALLATION - CONTINUED

8.

Calculate difference between lowest and highest measurement. Differences must not be greater than limit, as shown in

Table 1.

9.

Remove link bracket and lifting equipment from fly-

wheel housing (2).

10.

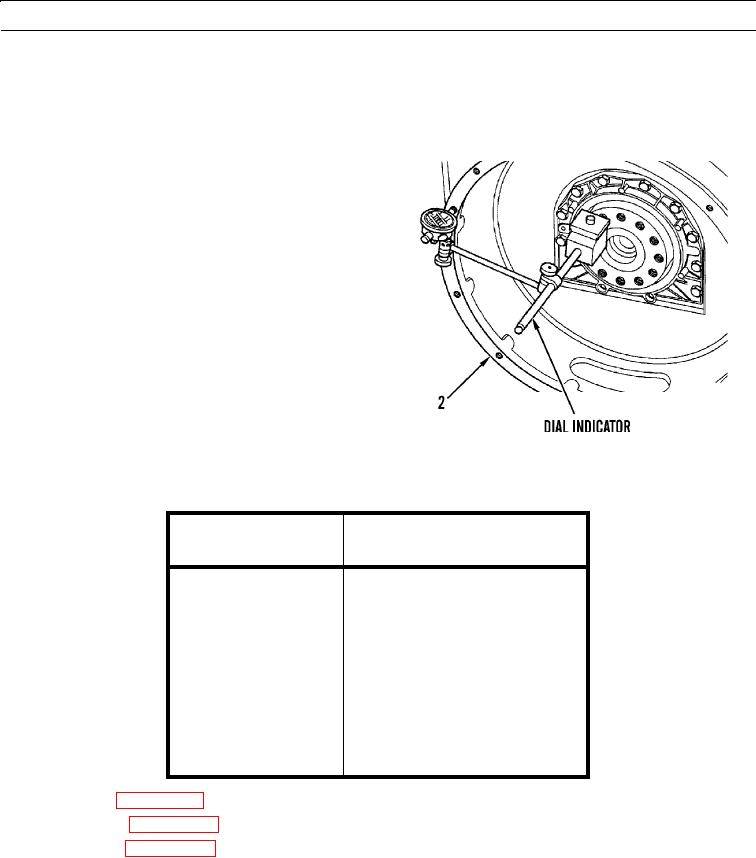

Install dial indicator (as shown).

11.

Set pointer of dial indicator to 0.00 in. (0.00 mm).

12.

Check alignment at 90 degree intervals around fly-

wheel housing (2).

13.

Calculate difference between lowest and highest mea-

surements. Differences must not be greater than limit,

as shown in Table 1.

427-B0397

Table 1. Limits for Flywheel Housing Runout and Alignment (Total Indicator Reading).

MAXIMUM LIMIT

BORE OF HOUSING

(TOTAL INDICATOR READING)

14.25 in. (36.2 cm)

0.009 in. (0.23 mm)

16.14 in. (41.0 cm)

0.010 in. (0.25 mm)

17.63 in. (44.8 cm)

0.011 in. (0.28 mm)

20.11 in. (51.1 cm)

0.012 in. (0.30 mm)

22.99 in. (58.4 cm)

0.014 in. (0.36 mm)

25.51 in. (64.8 cm)

0.016 in. (0.41 mm)

30.98 in. (78.7 cm)

0.019 in. (0.48 mm)

14.

Install starter (WP 0048 00).

15.

Install flywheel (WP 0150 00).

16.

Check oil level (WP 0025 00).

17.

Run engine until normal operating temperature is reached (TM 5-3805-290-10).

18.

Shut down engine (TM 5-3805-290-10).

19.

Check for leaks.

END OF WORK PACKAGE

0151 00-4