TM 5-3805-290-23-2

FLYWHEEL REPLACEMENT - CONTINUED

0150 00

CLEANING AND INSPECTION - CONTINUED

Runout Check - Continued

6.

Calculate the difference between lowest and highest measurements. Difference must not be greater than 0.012 in. (0.30

mm).

7.

If runout is not within specification, replace flywheel or contact general support maintenance.

INSTALLATION

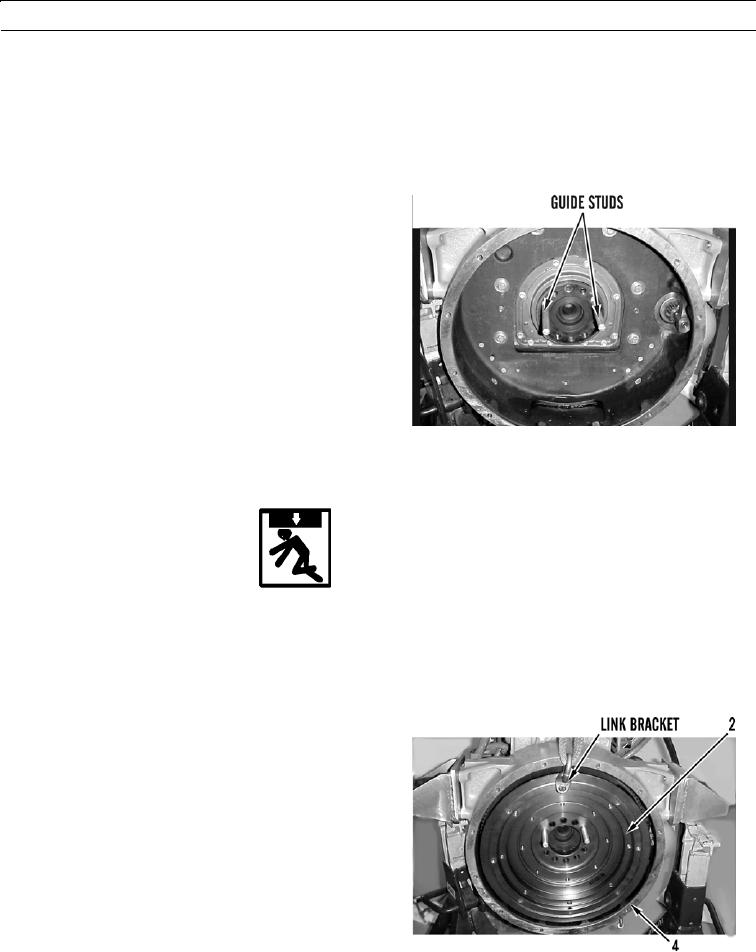

1.

Install link bracket and lifting equipment on flywheel

(2).

427-B0387

WARN I N G

Use extreme caution when handling heavy parts. Provide adequate support and use assistance during pro-

cedure. Ensure any lifting equipment used is in good condition and of suitable load capacity. Keep clear of

heavy parts supported only by lifting equipment. Failure to follow this warning may result in injury or

death to personnel.

N OT E

Flywheel weighs 120 lb (54 kg).

2.

With assistance, position flywheel (2) in housing (4).

427-B0389

0150 00-5