TM 5-3805-291-23-1

TROUBLESHOOTING WITHOUT A DIAGNOSTIC CODE - CONTINUED

0008 00

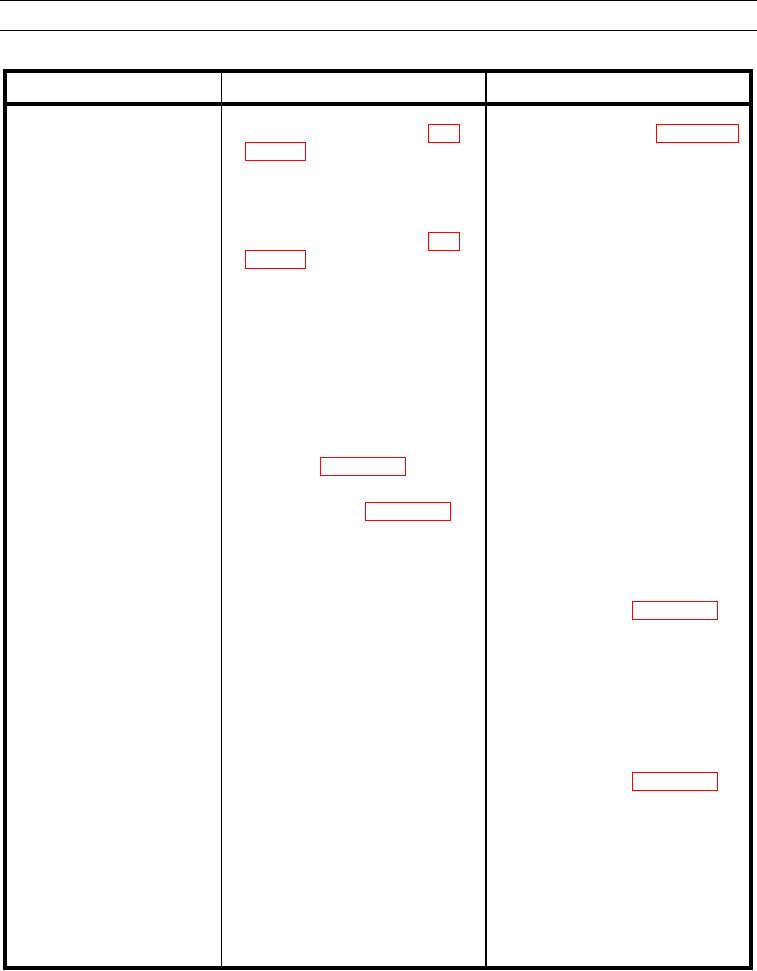

Table 7. Hydraulic System Troubleshooting - Continued.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

3. Perform Relief Valve (Main, Load

If problem still exists, perform Relief Valve

3.

Pump Output is Low -

Sensing) Test and Adjustment (WP

(Line) Test and Adjustment (WP 0017 00).

Continued.

1. Inspect hydraulic system for leaks.

1. Repair any leaks found.

4.

Oil Pressure is Low.

2. If problem still exists, go to Test 2.

2. Perform Relief Valve (Main, Load

1. Adjust as necessary.

Sensing) Test and Adjustment (WP

2. If problem still exists, replace control

valve (WP 0218 00).

3. If problem still exists, replace pump

(WP 0215 00).

1. Check for oil leaks around piston seals

1. If leaks are present, replace the leaky

5.

Work Tool Moves While

of lift and tilt cylinders.

cylinder (WP 0152 00 or WP 0153 00).

Control Lever is in HOLD

2. If problem still exists, go to Test 2.

Position.

2. Check for leak in line(s) between

1. Repair any leaks present (WP 0156 00

control valve and cylinder that is

or WP 0157 00).

drifting.

2. If problem still exists, go to Test 3.

3. Perform Main Control Valve (MSD)

If problem still exists, go to Test 4.

Calibration (WP 0017 00).

4. Perform Joystick Control Position

If problem still exists, go to Test 5.

Sensor Calibration (WP 0017 00).

5. Check for active diagnostic codes for 1. Troubleshoot any active diagnostic

the joystick position sensors (WP 0006

codes.

00).

2. If no codes are present and a joystick

position sensors is suspected, use

electrical schematic (WP 0236 00) to

troubleshoot joystick position sensors.

Replace joystick if sensor is faulty (WP

0219 00).

3. If problem still exists, go to Test 6.

6. Check for active diagnostic codes for

1. Troubleshoot any active diagnostic

the pilot hydraulic solenoid (WP 0006

codes.

00).

2. If no codes are present and a pilot

hydraulic solenoid is suspected, use

electrical schematic (WP 0236 00) to

troubleshoot pilot hydraulic solenoid.

Replace solenoid if faulty (WP 0218

00).

3. If problem still exists, replace main

control valve (WP 0218 00).