TM 5-3805-291-23-1

TROUBLESHOOTING WITHOUT A DIAGNOSTIC CODE - CONTINUED

0008 00

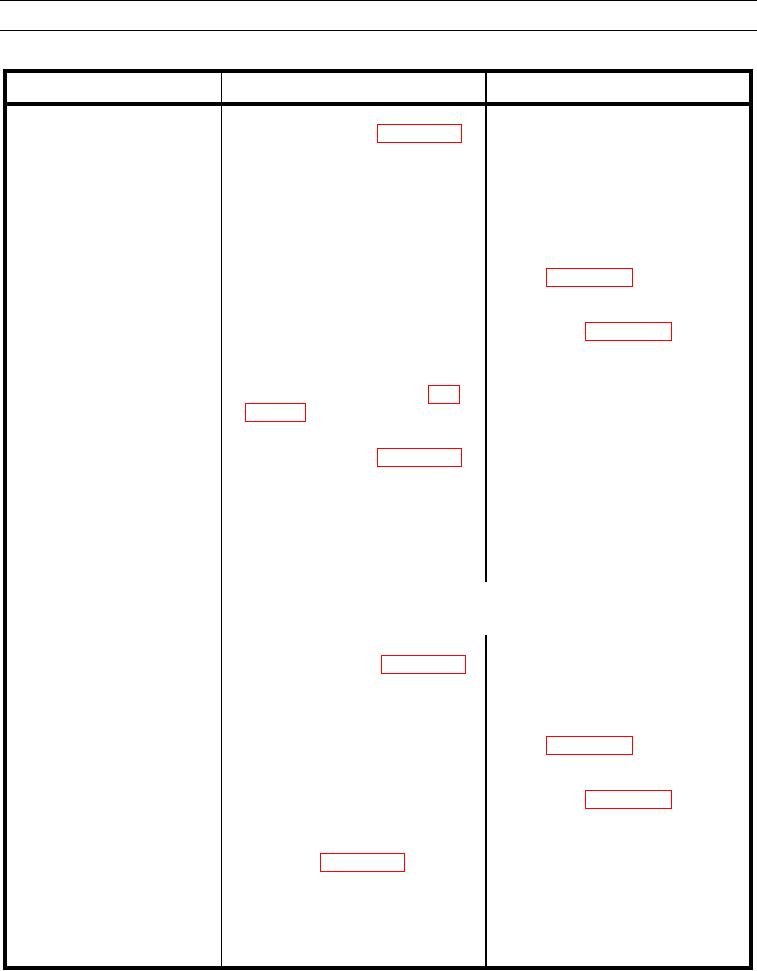

Table 7. Hydraulic System Troubleshooting - Continued.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

5. Perform Pilot Pressure to Main

If damaged replace main control valve

13. There is Too Much Tilt

Control Valve Check (WP 0017 00).

(WP 0218 00).

Cylinder Drift - Continued.

14. Hydraulic Force is Too Low 1. Ensure machine is being operated

1. Increased load could be impeding

within specified parameters (TM 5-

performance of machine.

When Tilt Control Lever is

3805-291-10).

2. If problem still exists, go to Test 2.

Moved to TILT BACK or

DUMP Positions.

2. Check for active diagnostic codes.

1. If any diagnostic code exist, refer to

Troubleshooting with a Diagnostic

Code (WP 0009 00).

2. If there are no diagnostic codes, then

perform Main Control Valve (MSD)

Calibration (WP 0017 00).

3. If problem still exists, go to Test 3.

3. Perform Relief Valve (Main, Load

1. Adjust as necessary.

Sensing) Test and Adjustment (WP

2. If problem still exists, go to Test 4.

4. Perform Pilot Pressure to Main

1. Adjust as necessary.

Control Valve Check (WP 0017 00).

2. If problem still exists, go to Test 5.

5. Inspect tilt cylinder for damage.

1. If damaged, replace tilt cylinders (WP

0152 00).

2. If problem still exists, go to Test 6.

6. Check for leaks or damage to lift

If faulty, replace control valve (WP 0218

cylinders.

00).

N OT E

15. Lift Cylinders Collapse

During Raise Operation.

Cylinder collapse is a sudden drop during normal operation.

1. Test operation and check calibration of 1. If faulty, replace pilot operated control

pilot operated control (WP 0017 00).

(WP 0218 00).

2. If problem still exists, go to Test 2.

2. Check for active diagnostic codes.

1. If any diagnostic codes exist, refer to

Troubleshooting with a Diagnostic

Code (WP 0009 00).

2. If there are no diagnostic codes, then

perform Main Control Valve (MSD)

Calibration (WP 0017 00).

3. If problem still exists, go to Test 3.

3. Perform Pressure Reducing Valve

1. Adjust as necessary.

Adjustment (WP 0017 00).

2. If problem still exists, go to Test 4.

4. Check nitrogen precharge on ride

1. Adjust as necessary.

control accumulator (WP 0151 00).

2. Go to Test 5.