TM 5-3805-291-23-1

FUEL SYSTEM TESTS, INSPECTIONS, AND ADJUSTMENTS - CONTINUED

0011 00

FUEL SYSTEM PRESSURE TEST - CONTINUED

Checking Fuel Pressure After Secondary Filter - Continued

C AU T I O N

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened component life.

Ensure fluids are contained during performance ofinspection, maintenance, testing, adjusting, and

repair.

Dispose of all fluids according to local regulations.

N OT E

Fuel pressure readings near fuel supply manifold have pressure spikes. Pressure spikes are caused by excess

fuel returning to fuel system from injectors. Excessive needle movement at gage may be present. Connect

gage with section of suitable hose. Air in the hose absorbs the spikes. This achieves an average reading and

a steady needle. Keep gage above measuring point.

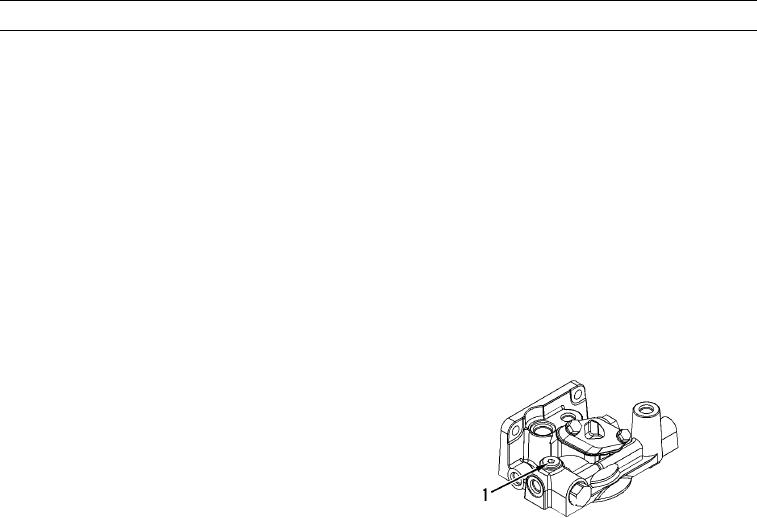

1.

Install differential pressure gage in port (1).

427-C0607

2.

Start engine (TM 5-3805-291-10).

3.

Run engine in no-load condition at 1,800 rpm (TM 5-3805-291-10).

N OT E

If excessive pressure is found, check the conditions listed under High Fuel Pressure in this work package.

4.

Record pressure. Fuel pressure should be 85 psi (586 kPa) nominal.

0011 00-6