TM 5-3805-291-23-1

FUEL SYSTEM TESTS, INSPECTIONS, AND ADJUSTMENTS - CONTINUED

0011 00

FUEL QUALITY TEST

0011 00

1.

Determine if water and/or contaminants are present in fuel by checking water separator (TM 5-3805-291-10).

N OT E

A full fuel tank minimizes potential for overnight condensation.

2.

Drain water separator, if necessary (TM 5-3805-291-10).

N OT E

Water separator can appear to be full of fuel when water separator is actually full of water.

3.

Determine if contaminants are present in fuel by removing sample of fuel from bottom of fuel tank (WP 0033 00).

N OT E

Color of fuel is not necessarily an indication of fuel quality. However, fuel that is black, brown, and/or

similar to sludge can be an indication of bacteria or oil contamination. In cold temperatures, cloudy

fuel indicates that fuel may not be suitable for operating conditions. Refer to Preventive Maintenance

Checks and Services (PMCS) (WP 0020 00) for recommended fuels.

4.

Visually inspect fuel sample for contaminants.

5.

Check fuel gravity with calibration fluid and diesel fuel test kit. Acceptable range of fuel gravity is 30 to 45 when API is

measured at 60F (15C), but there is a significant difference in energy within this range.

N OT E

Measured fuel API rating and corr sponding fuel temperature must be corrected to 60F (15C) before

e

selecting fuel correction factor. Use Table 1 for fuel density correction factor to determine fuel API rat-

ing at 60F (15C).

A correction factor greater than1.000 may cause low power and/or excessive fuel consumption.

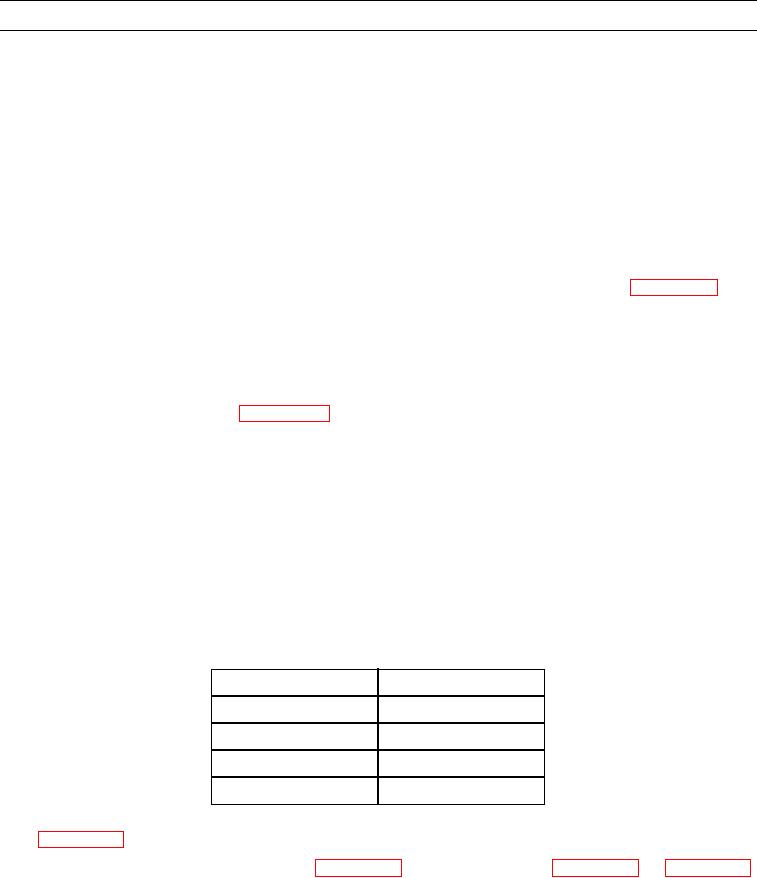

Table 1. Fuel Density (API).

API at 60F (15C)

Correction Factors

32.0

0.987

35.0

1.000

40.0

1.022

45.0

1.044

6.

If fuel quality is still suspected as a possible cause of engine performance problems, disconnect fuel inlet line from tank

(WP 0033 00). Temporarily operate engine from good source of fuel to determine if problem is caused by fuel quality.

7.

If fuel quality is the problem, drain fuel system (WP 0020 00) and replace fuel filters (WP 0035 00 and WP 0036 00).

Fill tank with good fuel (TM 5-3805-291-10). Engine performance can be affected by these characteristics:

a.

Cetane number of fuel.

b.

Air in fuel.

c.

Fuel mixed with other fluids.

0011 00-4