TM 5-3805-291-23-1

ELECTRICAL SYSTEM TESTS, INSPECTIONS, AND ADJUSTMENTS - CONTINUED

0013 00

INJECTOR SOLENOID CIRCUIT TEST - CONTINUED

427-C0697

3.

Check for logged diagnostic codes for injector solenoids.

a.

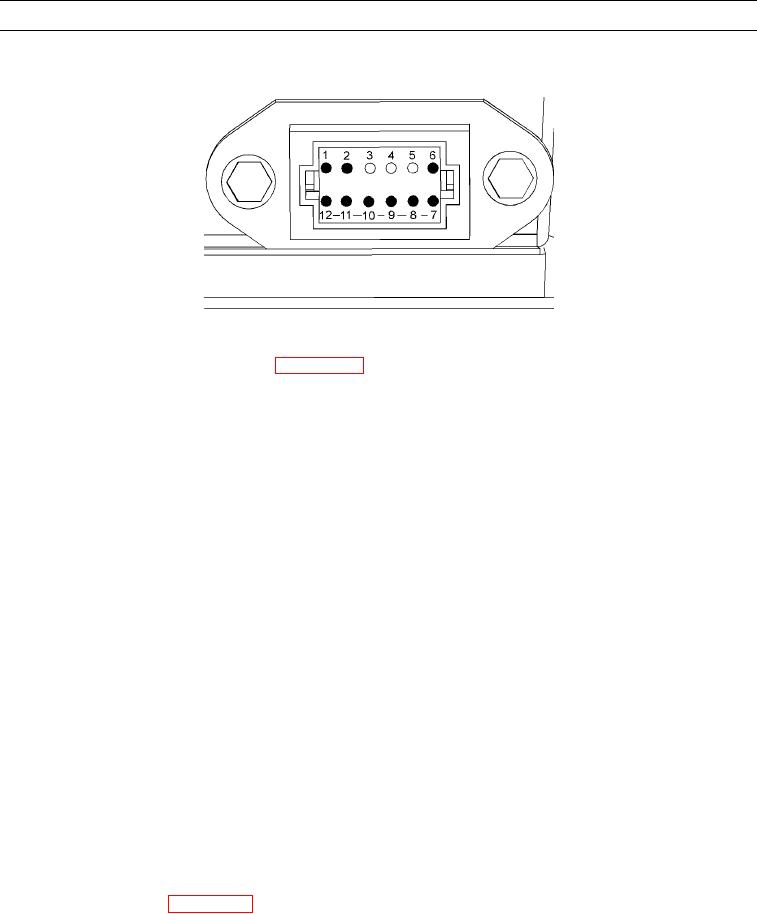

Connect ET to data link connector (WP 0005 00).

b.

Place battery disconnect switch in ON position (TM 5-3805-291-10).

c.

Check for logged diagnostic codes for injector solenoids on ET.

Expected Results. There are no logged diagnostic codes for injector solenoids.

d.

(1)

If results are OK, no diagnostic codes have been logged. Injector solenoids are operating correctly. There

may be a mechanical problem with injector's fuel delivery. Proceed to step 4.

(2)

If results are not OK, one or more diagnostic codes have been logged. There may be an electrical problem

in circuit for injector. Proceed to step 5.

4.

Use MSD to perform cylinder cutout test.

a.

Start engine (TM 5-3805-291-10).

b.

Allow engine to warm up to normal operating temperature (approximately 171F [77C]).

c.

After engine is warmed to operating temperature, access cylinder cutout test by accessing these display screens in

this order:

(1)

"Diagnostics"

(2)

"Diagnostic Tests"

(3)

"Cylinder Cutout Test"

d.

Shut off all parasitic loads such as air conditioning and air compressors which could affect results of test.

e.

Select Start button at bottom of screen for cylinder cutout test on ET.

f.

Follow instructions that are provided in cylinder cutout test. Cylinder cutout tests are interactive so procedure is

guided to finish. Cylinder cutout test will set correct engine speed for application.

Expected Results. Variation of fuel rate for all cylinders is within specifications.

g.

(1)

If results are OK, a problem with fuel system is suspected and diagnostic codes are not active or logged.

Refer to WP 0011 00 for information related to low pressure in fuel system. If a diagnostic code results

from running cylinder cutout test, proceed to step 5.

(2)

If results are not OK, cylinder cutout test indicates at least one injector is not operating correctly. Proceed

to step 5.

0013 00-57