TM 5-3805-291-23-1

BRAKE SYSTEM TESTS, INSPECTIONS, AND ADJUSTMENTS - CONTINUED

0015 00

SERVICE BRAKE WEAR INDICATOR (EXISTING BRAKE DISC) CHECK - CONTINUED

N OT E

Values shown on screen are baseline values fo each service brake. The "Brk Meas Hourmeter"

r

value is reading on SMU. The SMU reading was recorded when new brake discs were installed on

machine.

DO NOT modify measurements or "Brk Meas Ho rmeter" values stored in powertrain ECM.

u

Change these values only when installing new brake discs.

19.

Record each value of dimension (C) on piece of paper.

20.

Exit MSD software.

21.

Turn engine start switch to OFF position (TM 5-3805-

291-10).

22.

Disconnect MSD from diagnostic connector (WP

23.

Determine amount of service life available for left

front service brake discs. Write down value of dimen-

sion (C) for left front service brake. Write down base-

line value for left front service brake stored in

powertrain ECM.

427-C2019

24.

Subtract value of dimension (C) from baseline value.

Difference indicates amount of wear that has occurred

to service brake discs.

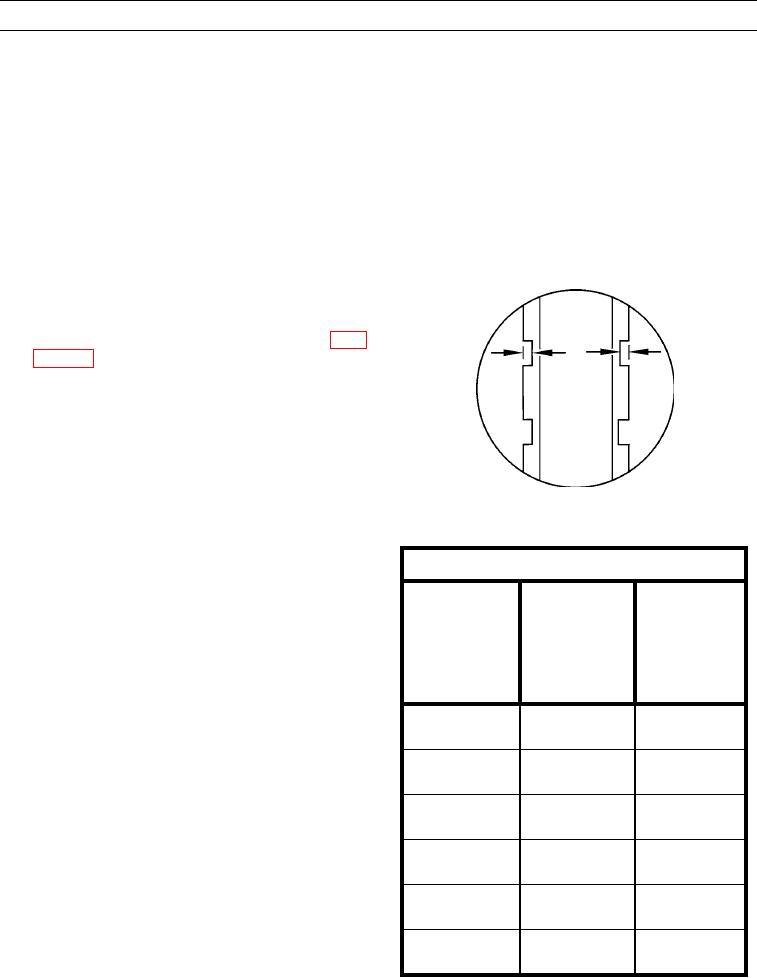

DISC THICKNESS WEAR CHART

N OT E

ESTIMATED

AMOUNT OF

PERCENTAGE

A difference of 0.058 in. (1.46 mm)

OF

MATERIAL

OIL GROOVE

or more indicates that discs must be

REMAINING

THAT IS

DEPTH

replaced.

BRAKE DISC

WORN FROM

LIFE

THE DISC

If you install a new brake disc in

any of the four service brakes, you

0.000 in.

0.041 in.

must enter a new baseline value.

100

(0.00 mm)

(1.05 mm)

25.

Repeat steps 3 thru 22 for other service brake discs.

0.011 in.

0.036 in.

80

(0.29 mm)

(0.90 mm)

N OT E

0.023 in.

0.030 in.

60

(0.58 mm)

(0.76 mm)

The oil groove depth is the most critical

0.034 in.

0.024 in.

dimension. If the depth of the oil

40

(0.88 mm)

(0.61 mm)

grooves on the brake disc is too shallow,

oil flow will be inadequate. This can

0.046 in.

0.018 in.

20

cause excessive wear and abrasion.

(1.17 mm)

(0.47 mm)

0.058 in.

0.013 in.

26.

To provide an estimate on the amount of service life

0

(1.46 mm)

(0.32 mm)

for a brake disc, refer to Disc Thickness Wear Chart.

0015 00-21