TM 5-3805-291-23-1

HYDRAULIC SYSTEM TESTS, INSPECTIONS, AND ADJUSTMENTS - CONTINUED

0017 00

LIFT AND TILT CYLINDER DRIFT CHECK - CONTINUED

Lift Cylinder Drift Check - Continued

7.

Start and run engine at low idle (TM 5-3805-291-10).

8.

Lower bucket to ground (TM 5-3805-291-10).

9.

Stop engine (TM 5-3805-291-10).

Tilt Cylinder Drift Check

WARN I N G

Injury or death to personnel can result from sudden movement of lift or tilt cylinders. Do not stand under

work tool while testing or adjusting lift or tilt cylinders.

N OT E

This test will check drift rate oftilt cylinders. The drift rates will change according to conditions

including: hydraulic oil temperature, type of bucket, load in bucket, etc.

Bucket should be empty during tests.

Auxiliary cylinders will drift in CLOSE (LOWER)direction because of orifice in rod end line.

Orifice connects to tank.

1.

Start and run engine at low idle (TM 5-3805-291-10).

2.

Warm hydraulic oil to 120 to 150F (49 to 65C) (TM 5-3805-291-10).

3.

To check lift circuit, raise bucket to maximum height and keep bottom of bucket parallel to ground. Move control lever

to HOLD position.

4.

Stop engine (TM 5-3805-291-10).

N OT E

If amount of cylinder drift is within specification, tilt circuit is not causing drift problem.

5.

Record cylinder rod movement. Maximum drift for different temperatures in Table 2 is 0.79 in. (20.0 mm).

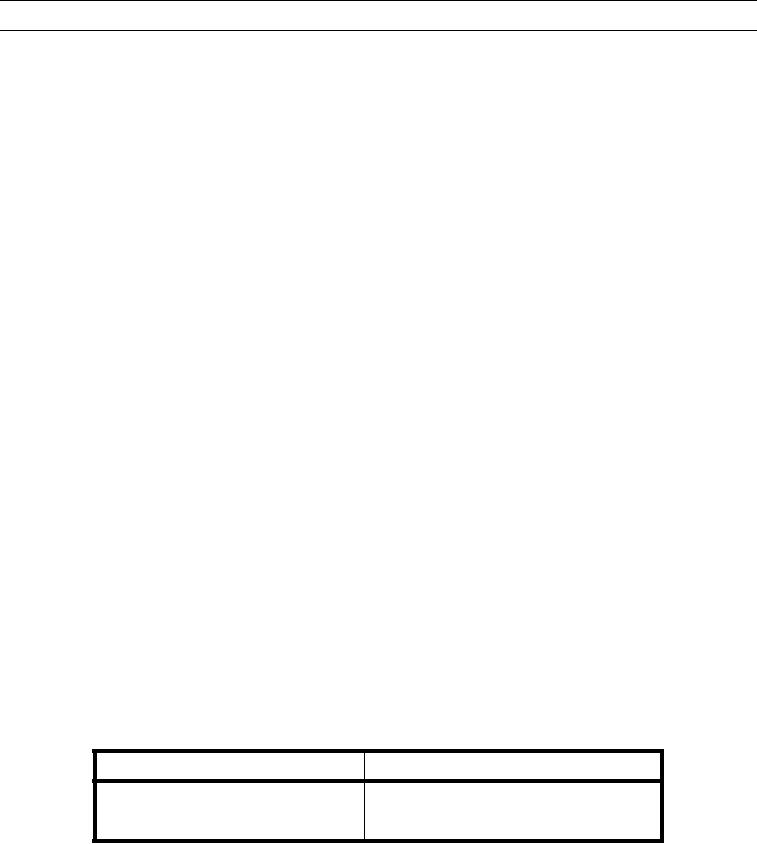

Table 2. Lift Cylinder Drift.

Oil Temperature

Time for Drift

122 to 149F (50 to 65C)

2.7 minutes

150F (66C) or more

1.7 minutes

If there is too much drift, check anti-drift valve for tilt function and check tilt back line relief valves (perform Relief

6.

Valve (Line) Set and Adjustment) in this work package.

7.

Start and run engine at low idle (TM 5-3805-291-10).

8.

Lower bucket to ground (TM 5-3805-291-10).

9.

Stop engine (TM 5-3805-291-10).

0017 00-46