TM 5-3805-291-23-2

PALLET FORKS REPAIR - CONTINUED

0167 00

DISASSEMBLY - CONTINUED

24.

Disconnect hose (34) from fitting (44) and remove hose from pallet fork assembly. Remove O-ring (36) from hose.

Discard O-ring.

25.

Remove fitting (44) from cylinder (23). Remove and discard O-ring (45).

26.

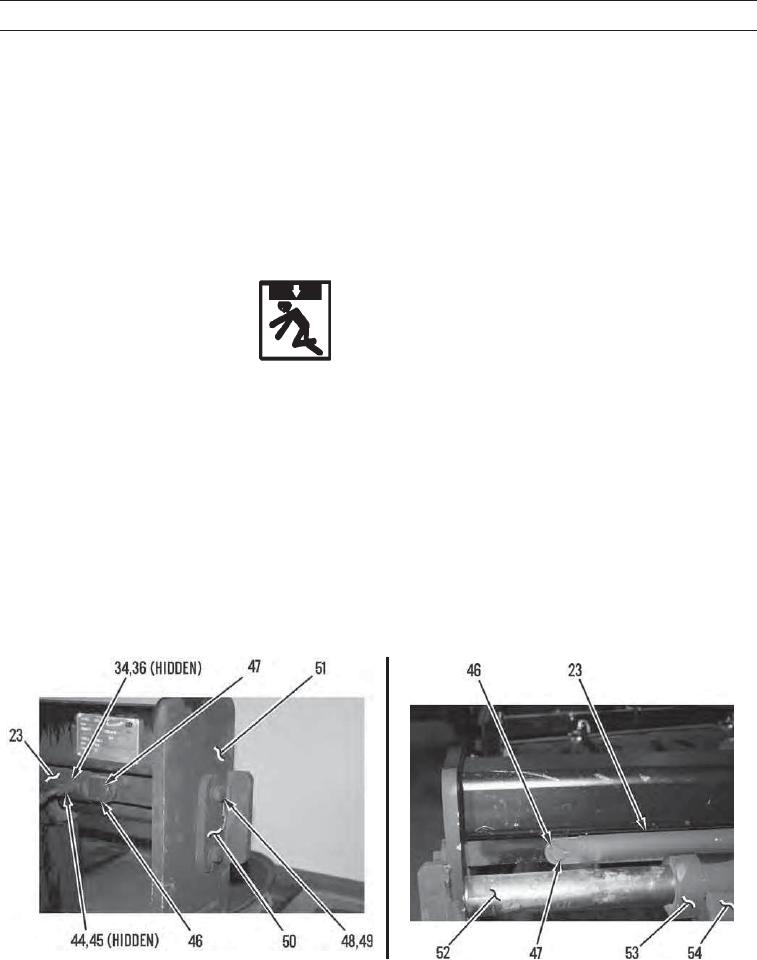

Remove two cotter pins (46) and pin (47) from cylinder (23). Discard cotter pins.

27.

Remove cylinder (23) from pallet fork assembly.

28.

Repeat steps 22, 23, and 27 to remove other cylinder (23).

29.

Remove two bolts (48) and washers (49) from pad (50) and remove pad from pallet fork assembly.

30.

Repeat step 29 for other side.

WARN I N G

Use extreme caution when handling heavy parts. Provide adequate support and use assistance during pro-

cedure. Ensure that any lifting equipment used is in good condition and of suitable load capacity. Keep

clear of heavy parts supported only by lifting equipment. Failure to follow this warning may result in injury

or death to personnel.

N OT E

Fork carriage weighs 1,920 lb (871 kg).

Tube weighs 260 lb (118 kg).

31.

Attach link bracket to pad (50) with washer (49) and bolt (48). Repeat for opposite side.

32.

Attach lifting equipment to fork carriage (51).

33.

Attach lifting equipment to tube (52).

34.

With assistance, carefully remove tube (52), two tine guides (53), and tines (54) from pallet fork assembly.

427-C1379

427-C1380

0167 00-4