TM 5-3805-291-23-2

FLYWHEEL HOUSING REPLACEMENT - CONTINUED

0176 00

CLEANING

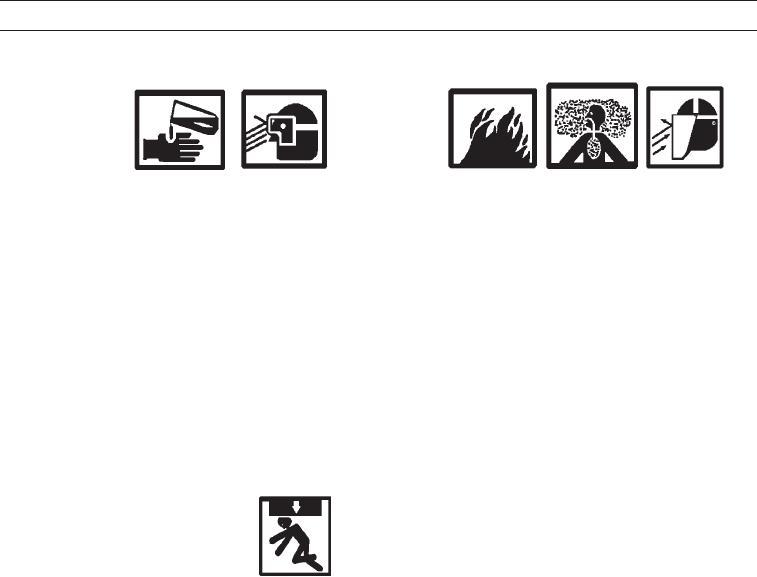

WARN I N G

Solvent cleaning compound MIL-PRF-680 Type III is an environmentally compliant and low-toxic

material. However, it may be irritating to the eyes and skin. Use protective gloves and goggles. Use in

well-ventilated areas. Keep away from open flames and other sources of ignition. Failure to do so may

result in injury or death to personnel.

Particles blown by compressed air are hazardous. DO NOT exceed 15 psi (103 kPa) nozzle pressure

when drying parts with compressed air. DO NOT direct compressed air against human skin. Make

sure air stream is directed away from user and other personnel in the area. To prevent injury, user

must wear protective goggles or face shield. Failure to follow this warning may result in injury to per-

sonnel.

1.

Remove all gasket material from mounting surfaces.

2.

Clean all parts and mating surfaces with solvent cleaning compound.

3.

Dry parts with compressed air.

INSTALLATION

WARN I N G

Use extreme caution when handling heavy parts. Provide adequate support and use assistance during pro-

cedure. Ensure that any lifting equipment used is in good condition and of suitable load capacity. Keep

clear of heavy parts supported only by lifting equipment. Failure to follow this warning may result in injury

or death to personnel.

C AU T I O N

Installation of flywheel housing on engine must be completed within 10 minutes of application of gasket

cement. Failure to do so could result in damage to equipment.

N OT E

Flywheel housing weighs approximately 137 lb (62 kg).

1.

Attach lifting equipment to flywheel housing (1).

2.

Apply gasket cement to face of engine.

3.

With assistance, position flywheel housing (1) on rear of engine.

4.

Install 12 washers (6) and bolts (5) on flywheel housing (1).

5.

Install bracket (4), two washers (3), and four bolts (2).

6.

Check flywheel runout as necessary.

0176 00-3