TM 5-3805-292-10

0020

Table 1. Preventive Maintenance Checks and Services (PMCS)

for the M400T and M400W SSL - Continued.

LOCATION

ITEM TO

CHECK/

ITEM

MAN-

NOT READY/

NO.

INTERVAL

HOURS

PROCEDURE

AVAILABLE IF:

SERVICE

59

After

Right-Side

Damage that would impair

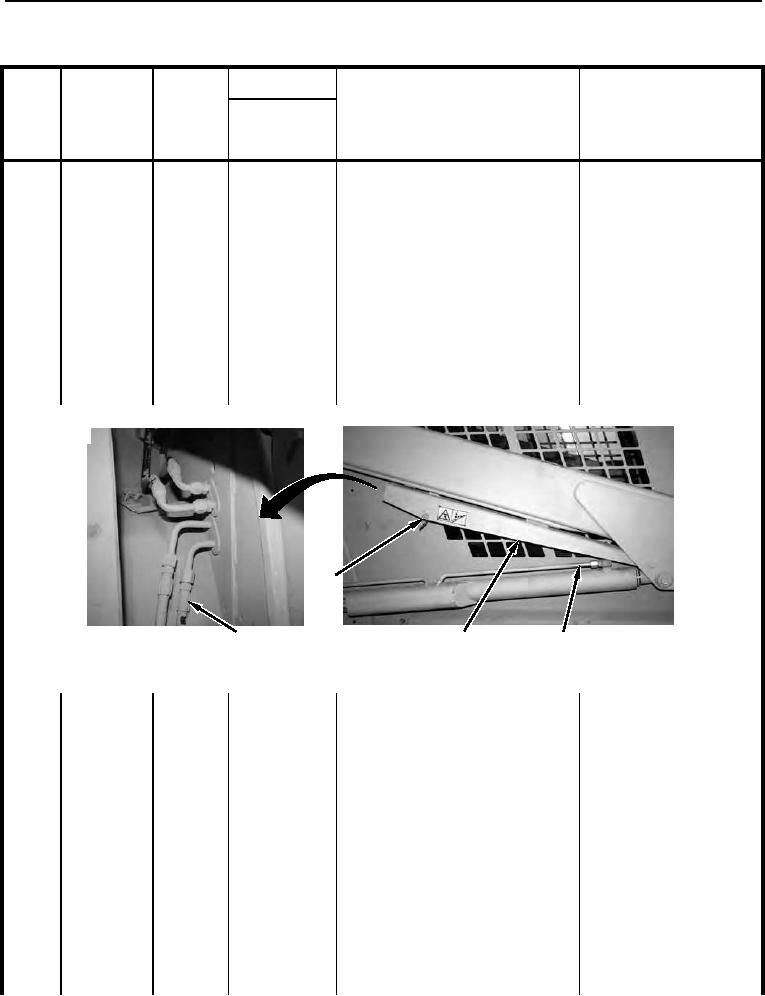

a. Inspect loader arm for cracks,

Loader Arm,

operation is evident.

breaks, or looseness of

Lift Cylinder,

mounting.

and Hydraulic

b. Inspect lift cylinder for damage

Damage or looseness is

Lines

and security of mounting.

evident.

c. Check for looseness or leaks in Looseness or Class III

hydraulic tubes, hoses, and

leaks are evident.

fittings.

d. Ensure loader support strut and Support strut damaged.

pin are securely installed to

loader arm and are not

damaged.

PIN

458-0884

HYDRAULIC TUBE

HYDRAULIC HOSES AND FITTINGS

LOADER ARM SUPPORT STRUT

Figure 46. Loader Arm Support Strut.

0020

60

M400T: Right- a. Check final drive for oil leaks.

After

Class III oil leaks are

evident.

Side Final

Drive and

Damage that would impair

b. Inspect sprocket teeth for cracks

Tracks

operation is evident.

or breaks.

c. Inspect track for cracks, breaks, Damage that would impair

or misalignment with sprocket. operation is evident.

Check track tread for cuts and

foreign material. Remove any

foreign material lodged in tread.

d. Ensure mud scraper and track

adjustment access plate are

present and securely mounted.

0020-52