TM 5-3805-292-10

0020

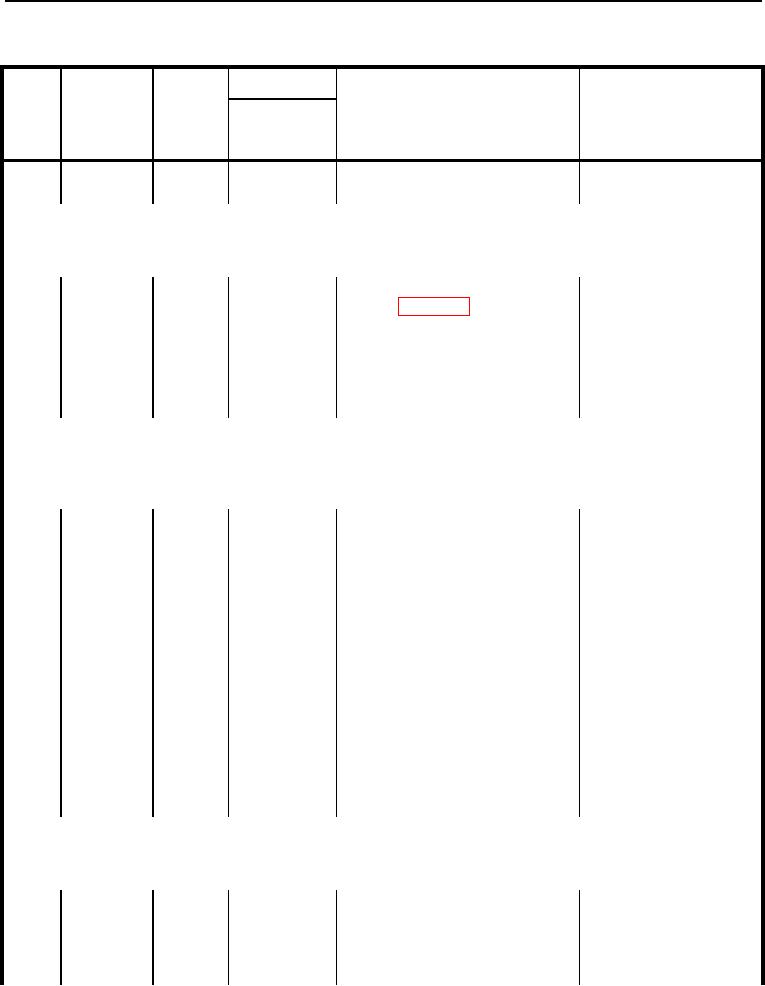

Table 1. Preventive Maintenance Checks and Services (PMCS)

for the M400T and M400W SSL - Continued.

LOCATION

ITEM TO

ITEM

MAN-

CHECK/

NOT READY/

NO.

INTERVAL

HOURS

SERVICE

PROCEDURE

AVAILABLE IF:

67

50 Hours

Track Tension

(M400T ONLY)

NOTE

If machine is new or tracks are new, track tension should be checked after initial 10 hours

of operation.

Check track tension and adjust as

required (WP 0023).

68

50 Hours

M400W: Right- a. Check for loose or missing axle

Any axle mounting

Side Axles,

mounting hardware.

hardware is missing.

Chain Tank,

b. Check chain tank for oil leaks.

Class III oil leaks are

Wheels and

evident.

Tires

NOTE

If machine is new or a new wheel and tire assembly has just been installed, wheel lug nuts

should be checked by Field Maintenance every 10 hours until nuts remain at torque.

Torque is 100 to 120 lb-ft (135 to 163 Nm).

c. Check for loose or missing

Two or more lug nuts are

wheel lug nuts.

missing.

d. Inspect tires and rims for

Damage to tire and/or rim

damage. Check tire tread and

that would lead to tire

sidewall for cuts and foreign

failure is evident.

material in treads. Remove any

foreign material lodged in tire

tread.

e. Examine rolling radius of tires

Tire is flat.

for an indication of tire inflation.

f. Ensure valve stems and caps

are present and in good

condition.

69

Initial 50

Engine Oil and

Hours

Oil Filter

NOTE

If machine is new, or engine is new, engine oil and oil filter should be serviced after initial 50 hours of

operation.

Notify Field Maintenance to change

engine oil and replace oil filter.

0020-57