TM 5-2420-231-23-2

0217

DISASSEMBLY CONTINUED

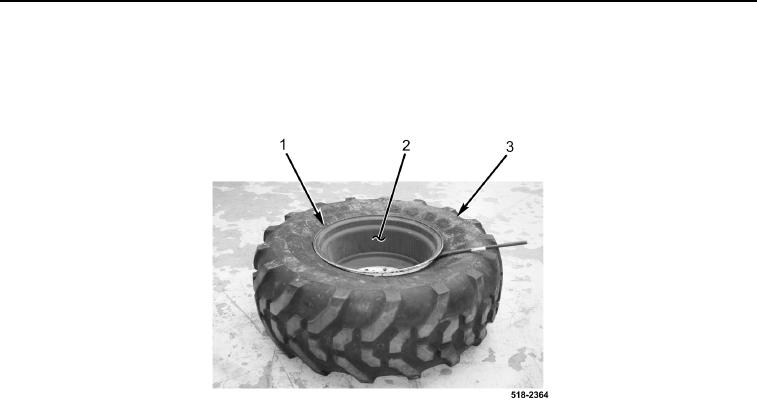

5. With assistance, remove inner tire bead from rim (Figure 3, Item 1). Work around rim until tire bead is above

rim.

6. With assistance, remove outer tire bead from rim (Figure 3, Item 1). Work around rim until tire is free of rim.

Figure 3. Removing Rim from Tire.

0217

END OF TASK

CLEANING AND INSPECTION

0217

Clean and inspect all parts IAW Mechanical General Maintenance Instructions (WP 0369).

Rim Inspection

000217

1. Inspect rim, lockring, and flanges for damage or wear.

2. Inspect rim components for cracks, splits, or tears.

3. Remove rust, oil, and tire and rim lubricant residue from rim.

END OF TASK

ASSEMBLY

0217

CAUTION

Use tire and rim lubricant as necessary to avoid damaging tire beads or bead seats during

demounting and mounting. Never use petroleum-based products such as oil or grease

when demounting/mounting tires from rims. Petroleum-based products have a severe

degrading effect on tire rubber. Use only approved tire and rim lubricant. Failure to follow

this caution may result in damage to equipment.

NOTE

Tires are directional. Refer to tire sidewall for direction of rotation.

1. Place rim flat on floor.

2. Lubricate both beads of tire and place tire on rim.

3. Install inner bead on rim (Figure 3, Item 1) and work around rim until inner tire bead is on rim.

4. Install outer tire bead on rim (Figure 3, Item 1) and work around rim until tire bead is completely on rim.