TM 5-3805-255-14

0018

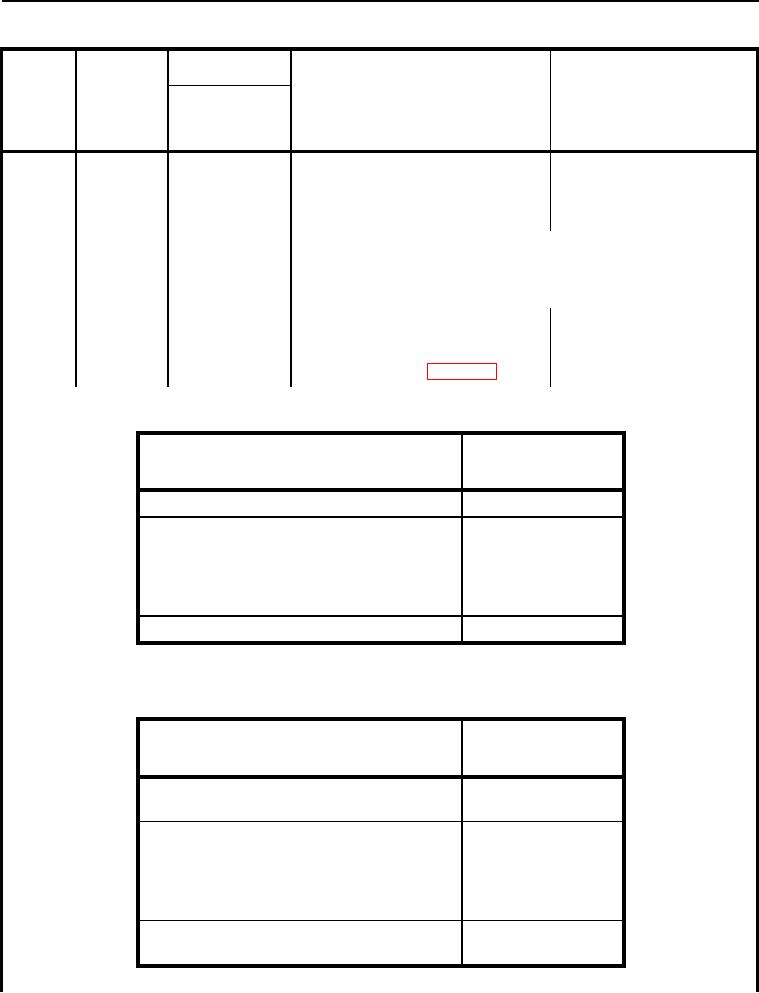

Table 1. Field PMCS for the H100C Loader - (Continued).

LOCATION

ITEM TO

CHECK/

NOT FULLY MISSION

SERVICE

CAPABLE IF:

ITEM NO. INTERVAL

PROCEDURE

c. Move alternator out to tighten belt,

Monthly

Alternator Belt

20

or in to loosen belt, until correct

Adjustment

(Cont.)

tension is obtained. Refer to Table 4

and Table 5.

CAUTION

Excess belt tension will damage alternator bearings. If a pry bar

is used, DO NOT OVER TENSION.

d. Tighten brace bolt and mounting

bolt.

e. Install fan guard (WP 0005).

Table 4. Belt Tension Chart.

ALTERNATOR BELT

CONDITION

New Belt Installation

70 to 75 lb

New Loader Upon Delivery

60 to 65 lb

1 Hour After Belt Replacement

After 10 Hours of Operation

After 50 Hours of Operation

At Intervals of 200 Hours

Minimum Permissible Tension

45 lb

Table 5. Belt Tension Chart (Deflection Method).

ALTERNATOR BELT

CONDITION

New Belt Installation

7/8 in.

(22 mm)

New Loader Upon Delivery

29/32 in.

1 Hour After Belt Replacement

(23 mm)

After 10 Hours of Operation

After 50 Hours of Operation

At Intervals of 200 Hours

Minimum Permissible Tension

1 in.

(25 mm)

0018-28