TM 5-3805-255-14

0018

Table 1. Field PMCS for the H100C Loader - (Continued).

LOCATION

ITEM TO

CHECK/

NOT FULLY MISSION

CAPABLE IF:

SERVICE

ITEM NO. INTERVAL

PROCEDURE

Annually

Engine Valve

d. Rotate camshaft one full revolution

23

Clearance

so No. 6 cylinder is at TDC

(Cont.)

Adjustments

(compression). In this position, adjust

intake valve bridges and valves for

cylinders 3, 5, and 6, and exhaust

valve bridges and valves for cylinders

2, 4, and 6 in same manner described

in steps b and c.

e. Install new gaskets and valve

covers.

Initial 100

Engine Cylinder

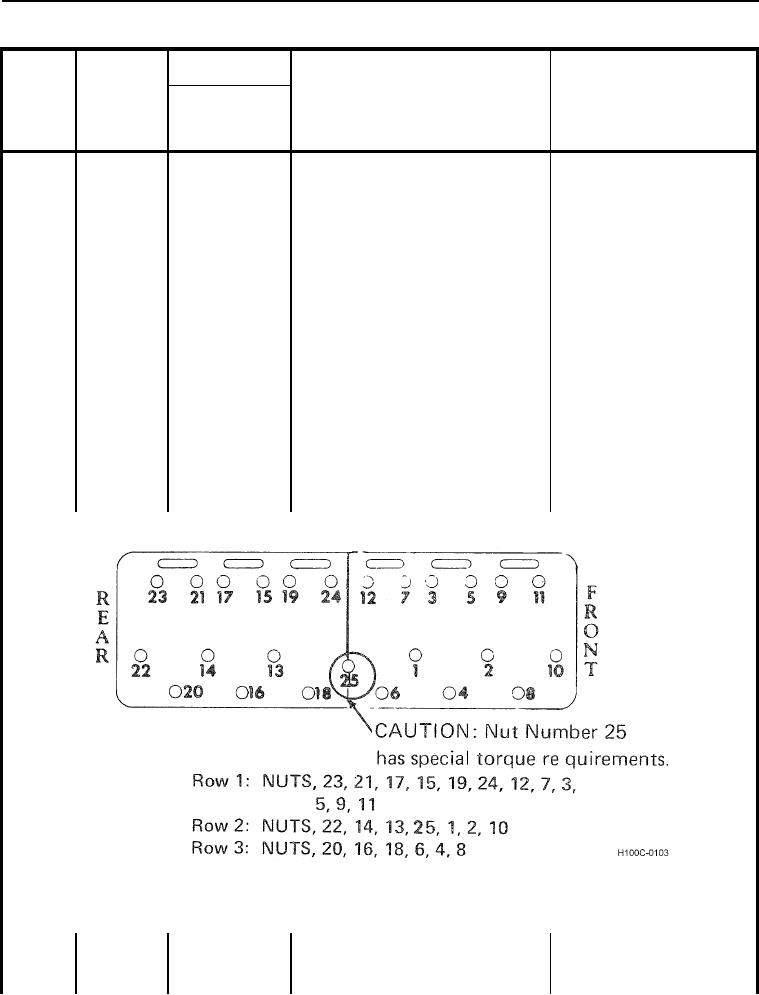

After initial 100 hours of new cylinder Broken bolts, cylinder head

24

head operation, torque cylinder head gasket leaking.

Hours

Head

nuts in sequence shown (Figure 19).

With engine at operating temperature,

loosen one nut at a time (1/4 turn) and

torque in rows as shown to 300 lb-ft

(407 Nm) except for nut #25, which is

to be torqued to 420 lb-ft (543 Nm).

Figure 19. Engine Cylinder Head Torquing Sequence.

0018

0018-33