TM 5-3805-255-14

0087

CLEANING, INSPECTION, AND REPAIR

00087

Cylinder Sleeves

00087

1. Clean and inspect all parts IAW General Maintenance Instructions (WP 0019).

CAUTION

Do not clean or reuse O-rings.

Do not use abrasive material to clean cylinder sleeves. Failure to follow these instructions

may result in damage to the equipment.

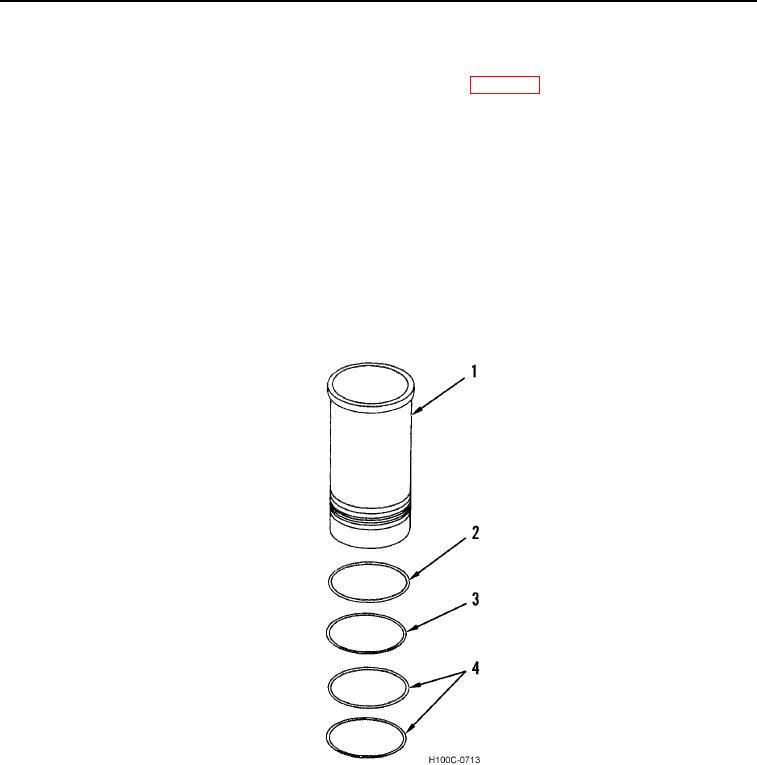

2. Remove O-ring (Figure 3, Item 3), shim(s) (Figure 3, Item 2) (if equipped), and two black packing O-rings

(Figure 3, Item 4) from cylinder sleeve (Figure 3, Item 1). Discard O-rings.

3. Measure inside diameter of sleeve (Figure 3, Item 1) with an inside micrometer or bore gauge from top to

bottom of sleeve where it is subject to piston and ring travel. Take measurements at right angles to determine if

sleeve is out-of-round or excessively tapered. See Table 1 for maximum allowable sleeve wear. If sleeve does

not meet specifications it must be discarded and a new piston sleeve (and piston) installed.

Figure 3. Cylinder Sleeve with Packing Rings and Shims.

0087

0087-4