TM 5-3805-255-14

0087

CYLINDER SLEEVES INSTALLATION CONTINUED

NOTE

Each cylinder may be adjusted independently. It is acceptable to use shims of one

thickness in one cylinder, and shims of another thickness in a different cylinder to arrive at

correct total cylinder sleeve height for proper combustion seating.

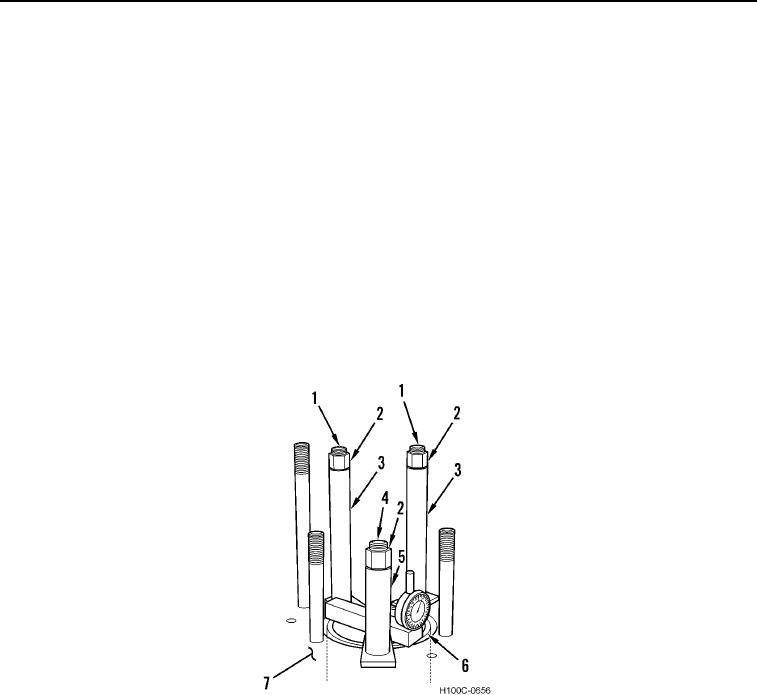

3. Install cylinder sleeve (Figure 8, Item 6), without O-rings, into crankcase (Figure 8, Item 7). Clamp sleeve down

by placing a sleeve holding adapter over three cylinder studs (Figure 8, Items 1 and 4).

NOTE

All pipes must be square and flat on both sides.

4. Place three pipes (Figure 8, Items 3 and 5) with a maximum ID of 1.00 in. (25 mm) over same three studs

(Figure 8, Items 1 and 4). For long studs (Figure 8, Item 1) use 8.500 in. (215 mm) long pipe (Figure 8, Item 3)

and 4.500 in. (115 mm) pipe for short stud.

5. Place regular cylinder head nuts (Figure 8, Item 2) on three studs (Figure 8, Items 1 and 4). Torque nuts

(Figure 8, Item 2) to 150 lb-ft in three stages of 50 lb-ft (68 Nm), 100 lb-ft (135 Nm) and 150 lb-ft (155 Nm).

Figure 8. Cylinder Sleeve Clamping.

0087

0087-9