TM 5-3805-255-14

0087

CLEANING, INSPECTION, AND REPAIR CONTINUED

00087

6. Machine top of insert to be flush to 0.002 in. (0.051 mm) above crankcase top deck without removing any metal

from crankcase top deck.

7. Record cylinder sleeve protrusion measurements from crankcase top deck and not insert. The amount of clear-

ance between deck of crankcase and top surface of sleeve flange must not exceed 0.002 to 0.004 in. (0.050 to

0.100 mm).

END OF TASK

CYLINDER SLEEVES INSTALLATION

00087

CAUTION

Whenever cylinder heads are removed, new head gaskets must be used. The pressure

contact surfaces of integral gasket rings are grooved to provide a better seal. This surface

flattens out when heads are torqued and may destroy sealing effect if reused. Check

cylinder sleeve flange protrusion as described in this procedure. After sleeve flange

protrusion has been determined, adjust cylinder to obtain correct total height (shims)

required for proper combustion sealing. Failure to follow these instructions may result in

damage to equipment.

When shimming of sleeve is necessary to obtain proper protrusion, it is best to use no

more than two shims, and only one if possible, per sleeve. If more shims are used, they

may set or extrude from their position. If necessary, resurface counterbore and use a

thicker shim rather than using more shims of a smaller size. The total thickness of all

shims used per sleeve cannot exceed 0.064 in. (1.63 mm). Failure to follow these

instructions may result in damage to equipment.

1. Follow instructions that pertain to existing condition of your engine.

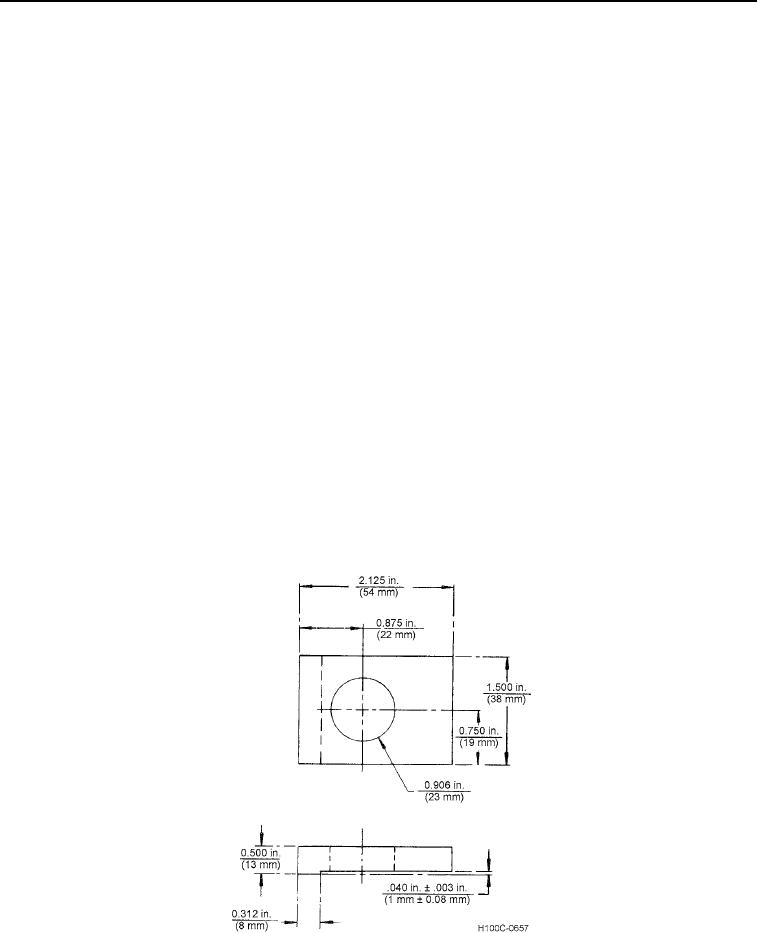

2. Construct Cylinder Sleeve Holding Adapter using locally obtained materials as shown in Figure 7.

Figure 7. Cylinder Sleeve Holding Adapter.

0087

0087-8