TM 5-3805-255-14

0087

CYLINDER SLEEVES INSTALLATION CONTINUED

Crankcase Counterbore Refacing

00087

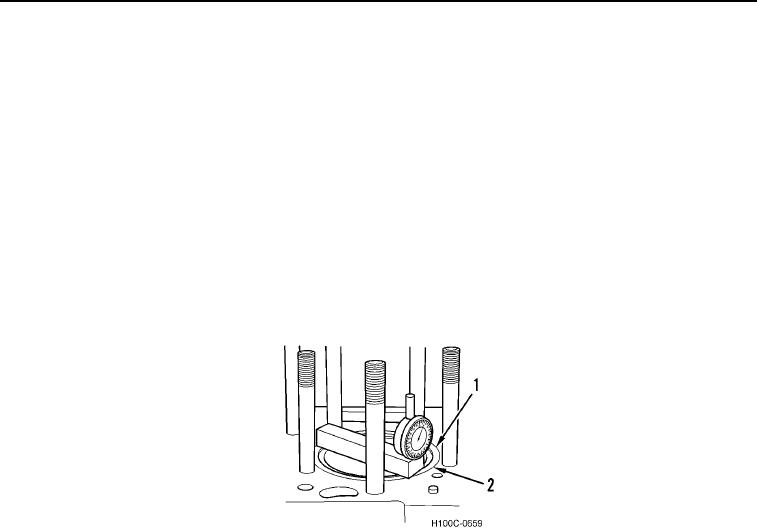

1. If sleeve flange protrusion was found to be more than 0.003 in. (0.08 mm) below crankcase deck (Figure 10,

Item 1), crankcase counterbore (Figure 10, Item 2) must be refaced.

NOTE

When shimming of cylinder sleeve is necessary to obtain proper protrusion, it is best to

use no more than two shims (and only one if possible) per sleeve. If more shims are used,

they may set or extrude from their position. If necessary, resurface counterbore and use a

thicker shim rather than using more shims of a smaller size. Total thickness of all shims

used per sleeve cannot exceed 0.064 in. (1.63 mm).

2. After counterboring, place necessary shims under sleeve flange to raise it up to 0.002 to 0.004 in. (0.05 to

0.010 mm) above crankcase deck.

Figure 10. Checking Crankcase Counterbore Depth.

0087

0087-11