TM 5-3805-255-14

0090

CLEANING, INSPECTION, AND REPAIR

00090

NOTE

Crankshaft must not be straightened

1. Clean and inspect all parts IAW General Maintenance Instructions (WP 0019).

2. Hardness must be checked on every journal which incurred a bearing failure, shows evidence of overheating

or before grinding crankshaft. Using a Rockwell Hardness Tester, check in at least three locations as close to

fillet as possible. Also, check rod journals at top, bottom, and one other location (top and bottom determined

with journal at TDC). Minimum hardness for non-fillet hardened shafts is 30 Rc. These shafts have an identifi-

cation number, 277 100 R1 or R2, forged into center cheek. Fillet hardened shafts, forged number 670 331 C1,

must have a minimum hardness of 45 Rc. If any reading is below this, shaft must be scrapped.

3. Inspect crankshaft journals for scoring and measure diameter of each journal, using a micrometer. Check

dimensions obtained against those specified in following table:

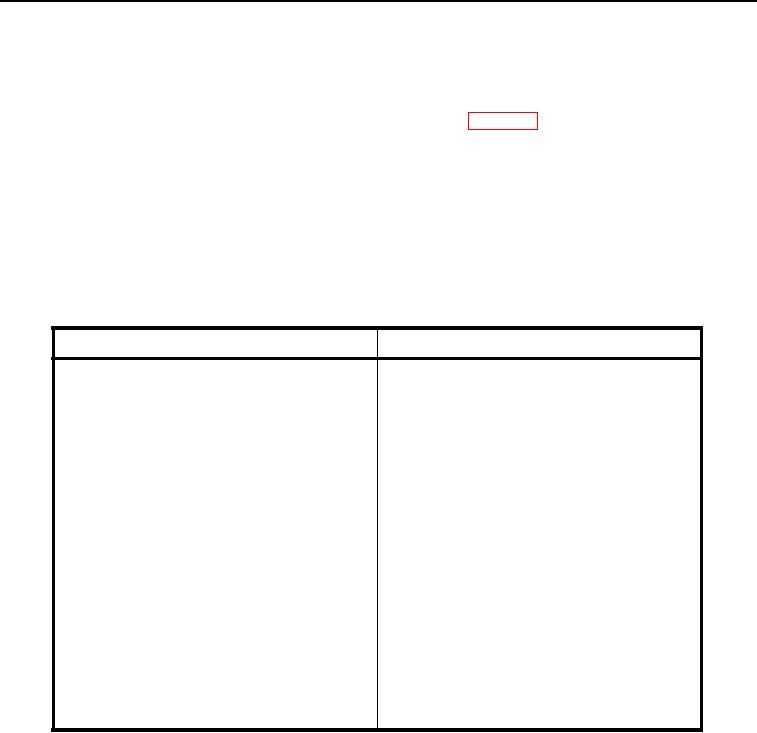

Table 1. Crankshaft Specifications.

SPECIFICATION

ITEM

090

090

Crankshaft Pin Diameter

3.4965 to 3.4975 in. (88.811 to 88.837 mm)

Main Journal Diameter

4.4990 to 4.5000 in. (114.275 to 114.300 mm)

Maximum Permissible Journal Out-of-Round-

0.004 in. (0.10 mm)

ness, Before Reconditioning

Number of Main Bearings

7

Main Bearing Running Clearance

0.0026 to 0.0060 in. (0.066 to 0.152 mm)

Maximum Permissible Bearing Running Clear-

0.0086 in. (0.218 mm)

ance

End-Play Clearance

0.005 to 0.011 in. (0.13 to 0.28 mm)

Maximum Permissible End-Play Clearance,

0.024 in. (0.61 mm)

Before Reconditioning

Counterbalanced Crankshaft

Yes

Main Bearing Bore in Crankcase (Line-

4.844 to 4.845 in. (123.04 to 123.06 mm)

Reamed with caps assembled)

0090-7