TM 5-3805-255-14

0090

CLEANING, INSPECTION, AND REPAIR CONTINUED

8. Inspect crankcase for sludge deposits, especially in corners. Crankcase must be thoroughly cleaned and

inspected. Remove oil gallery plugs and flush out passages in crankcase with fuel oil. Install plugs.

9. Replace front and rear main oil seals. Refer to Installation in this work package for rear main oil seal

replacement details. For front main oil seal replacement refer to WP 0088. Discard front and rear main oil seal.

10. Remove and clean crankcase breather element. Element is located in mounting flange of breather pipe which

is secured to right hand (rear) side of crankcase.

11. Inspect oil pan and clean thoroughly.

END OF TASK

CRANKSHAFT BEARING CAPS

00090

Crankshaft main bearing caps are rough machined and line reamed while fitted to crankcase. Each cap is fitted for

its respective position.

Dimensions of Main Bearing Bore in Crankcase

00090

Line-Ream Final To . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.844 to 4.845 in. (123.04 to 123.06 mm)

END OF TASK

INSTALLATION

00090

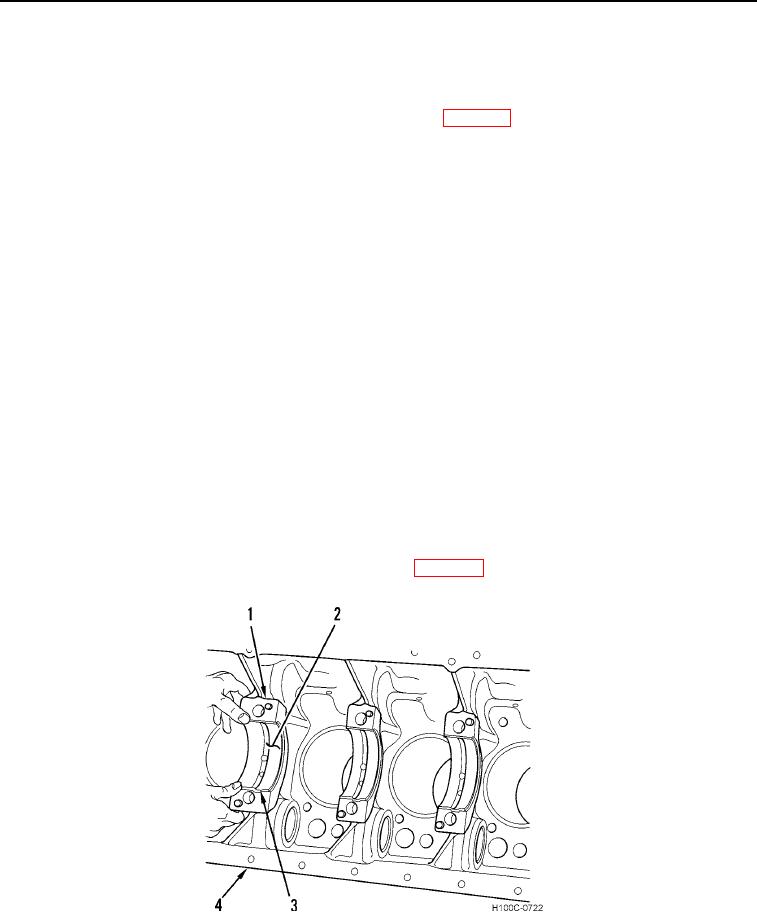

1. Wipe seven crankcase bearing supports (Figure 9, Item 1) free of oil with a lint-free clean cloth. Crankcase

(Figure 9, Item 4) must be bottom side up and supported level with blocks.

2. Install seven main bearing upper halves (Figure 9, Item 2) (bearings with oil hole in center) on crankcase

bearing supports (Figure 9, Item 1). If original bearings are being reinstalled, be sure that they go to positions

from which they came. Nibs of bearings must fit in notches (Figure 9, Item 3) on crankcase bearing supports.

Lubricate main bearing upper halves with clean engine oil (WP 0018).

Figure 9. Installing Upper Halves of Main Bearings.

0090

0090-11