TM 5-3805-255-14

0095

VALVE RECONDITIONING CONTINUED

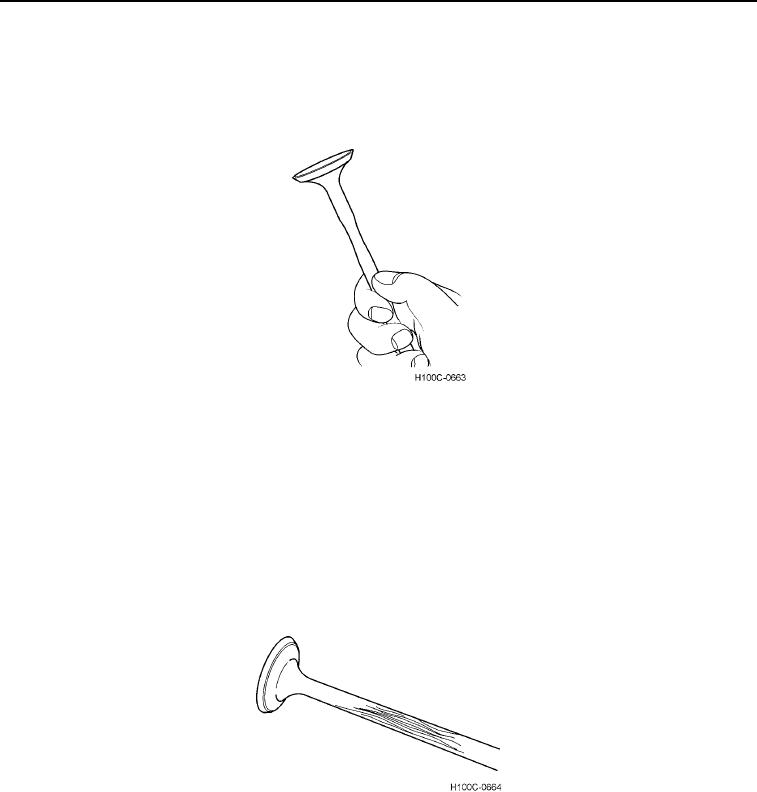

3. Discard severely burned valves (metal behind burn has lost its original properties). Valves which show

indications of "necking" must also be discarded. Necking is evidenced by a reduced diameter of valve stem

above port end of guide and is result of hot corrosion (Figure 4). Necked valves are susceptible to breakage, a

most expensive type of failure, since engine may be badly damaged when a valve head breaks off.

Figure 4. Necked Valve Stem.

0095

4. Discard valves with badly scuffed stems (Figure 5). Rough stems cause rapid valve guide wear. If there are

only slight indications of scuffing at extremities of guide contact area and there is no appreciable reduction in

stem diameter, valves will continue to give satisfactory service.

5. Inspect for worn keeper grooves and damaged valve tips. If present, discard valve. Worn grooves allow

cocking of spring retainer which tends to tip valve in guide, increasing guide wear and in extreme cases

causing leakage across valve face. Similar results can be expected from use of valves having badly damaged

tips. Refacing machines usually have an attachment for reconditioning valve tip, however, where tip is badly

damaged, grinding may remove all case-hardened metal on tip. Valves with deep notches or grooves in tip

must be replaced.

Figure 5. Scuffed Valve Stem.

0095

0095-4