5. DO NOT SHORT ACROSS OR GROUND ANY TERMINALS

Warning: Do not stand or work in step area(s)

OF THE "DELCOTRON" OR REGUIATOR-

when machine is running - No room for a man in

this area when machine is turned.

Do not short across or ground any of the ter-

minals on the "Delcotron" or regulator. Any arti-

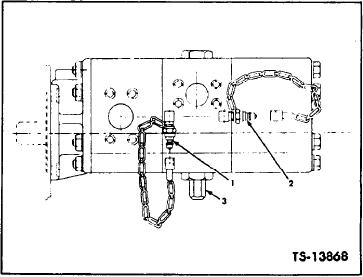

1. Use hydraulic pressure gauge of at least 3000

f i c i a l circuit set up by purposely grounding or

p s i capacity. With engine shut down, install

shorting any of the "Delcotron" or regulator ter-

gauge line on quick release fitting on steer pump

minals can cause serious electrical malfunctions

as shown in Figure 37, Item 1.

that might endanger components of the electrical

system.

2. Start engine and accelerate to maximum rpm;

then turn tractor to the right and hold against

6. DO NOT POLARIZE THE "DELCOTRON"-

stops.

D o not attempt to polarize the "Delcotron".

3. With the aid of a helper read gauge. Pressure

Polarizing the d.c. type of generator is necessary

reading should be as specified in Specifications

to insure that generator and battery polarity are

and Service Data section at rear of this manual.

the same. "Delcotron" polarizing however is not

necessary since the voltage developed within the

I f pressure reading is not as specified, shut

" D e l c o t r o n " is of both polarities and the diode

down engine, and inspect and check for collapsed

r e c t i f i e r automatically controls the direction of

or ruptured hoses, proper function of steering

current flow. It is of vital importance as discussed

cylinder packing glands, defective steering pump

in the first precaution that the battery ground and

or steering control valve.

the "Delcotron" g-round be of the same polarity for

diode protection.

If the above items are in satisfactory operating

condition it will be necessary to adjust the steering

7. BEFORE DOING ANY WELDING, DISCONNECT GROUND

pressure at the steering control valve.

CABLE FROM BATTERY AND ELECTRICAL LEAD FROM

BATTERY TERMINAL ON ALTERNATOR

1. Loosen locknut on steering control valve adjust-

ing screw.

Before doing any welding on machines equipped

w i t h an alternator, disconnect the ground cable

2. Turn tractor to extreme right or left and hold

from the battery and the electrical lead from the

a g a i n s t stops.

battery terminal on the alternator.

3. With transmission in neutral, accelerate to

Clean Axle Breathers: Each 500 operating

m a x i m u m rpm.

hours inspect breathers on front and rear axle

housings. Housing breathers have a loose fitting

4. Turn adjusting screw in increments of 1/4 rev-

cap that should be rotated.

Oil leakage past breathers, thrust caps, carrier

housing or pinion cap seals indicates that breath-

ers may be clogged. Unscrew breathers, wash in

solvent, dry and reinstall.

Check Steering Pressure: The steering hydrau-

lic pump is coupled to the drive line and operates

as soon as the engine is started. The pump draws

fluid from the reservoir and forces it under pres-

sure into the control valve mounted at the base of

the steering gear.

Maintenance consists of periodically checking

the pressure in the system.

2. Secondary Port

1. Primary Port

3. Acorn Nut

Note: Remove safety links, if attached between

front and rear frames.

Steering Pump Pressure Ports and Adjustment

Fig. 37.

[45-05-8]