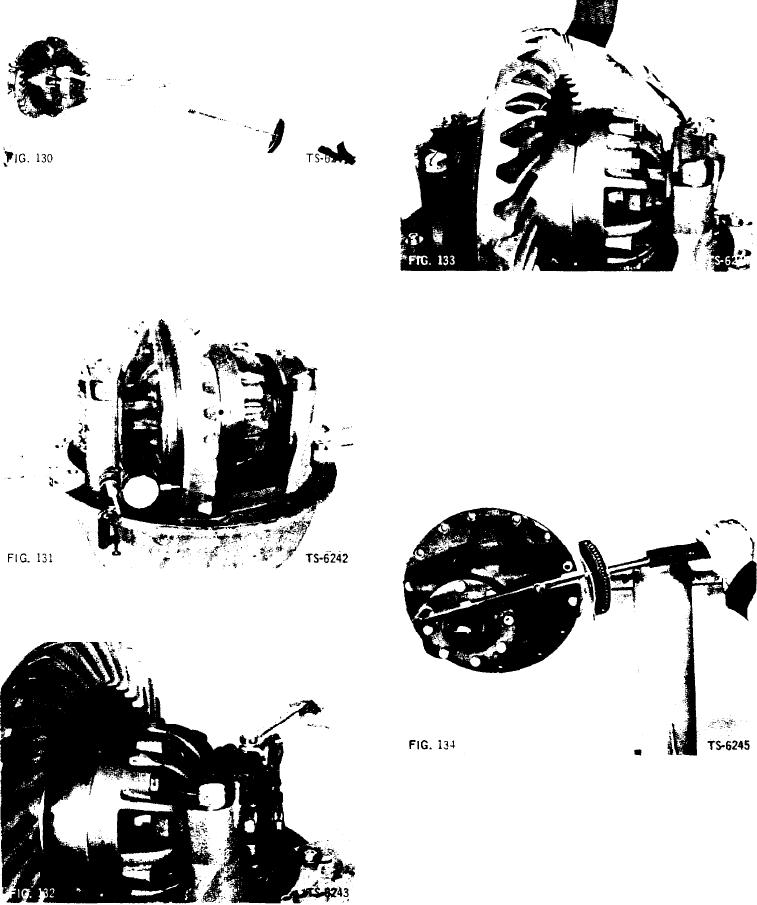

10. Tighten bearing cap bolts to specified torque (Fig.

13. Lockwire together the bearing cap bolts and adjusting

130). With dial indicator, recheck ring gear and

nut bolt (Fig. 133).

pinion backlash. Recheck differential bearings for

end play as described in step 4.

11. Use dial indicator to check back face of ring gear.

Rotate at least one full turn (Fig. 131). Runout must

not exceed .005 total indicator reading. If runout is

excessive, remove assembly and check for burrs or

dirt under mounting surface of ring gear. Reassemble

and recheck.

14. Remove companion flange and remove bolts and

washers that were used for temporary installation of

pinion shaft assembly. Coat outside diameter of seal

with Permatex No. 2 and press into pinion oil seal

retainer so that lip of seal will face toward pinion.

Coat lip with Lubriplate. Install gasket and pinion oil

seal retainer. Secure with 8 bolts and lockwashers

and tighten bolts to specified torque (Fig. 134).

12. Install adjusting nut lock with bolt and lockwasher

(Fig. 132).

15. On axle models that do not have a parking brake,

install companion flange on end of pinion shaft with

flat washer and nut. Torque nut to 600 ft. lbs. as

shown in Fig. 120. Secure nut with cotter pin. On axle

models with parking brake, companion flange should

be installed tempororily to facilitate handling the

differential.

[42]