11, Install four case bolts in alternate holes and tighten

its equivalent thickness. Use four pinion oil seal re-

them evenly until all are seated, taking care that No-

tainer bolts with flat washers to pull pinion shaft as-

SPIN parts do not bind (Fig. 117). Install remaining

sembly fully into carrier assembly (Fig. 119). Make sure

bolts and tighten all bolts to specified torque as

oil passages are aligned.

shown in Fig. 105.

NOTE: Some differential carrier housings have blind

tapped holes for mounting pinion shaft assembly. If

holes are blind, use stacks of flat washers on bolts

when installing pinion shaft assembly without oil seal

retainer to prevent bolts from bottoming in blind holes.

FIG. 117

TS-6208

12. After torquing bolts, insert axle shaft into differential

so that it engages side gear and check for backlash

between clutch teeth of No SPIN differential (Fig.

118). A backlash of approximately 5/32 inch must

be present. If proper backlash does not exist, dis-

assemble differential case halves and recheck for

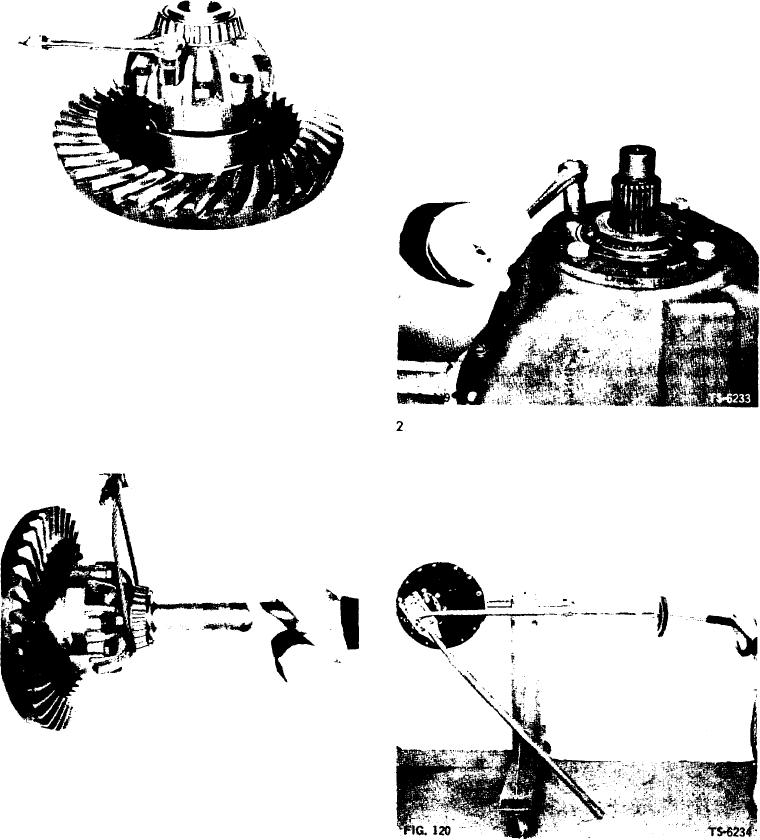

Temporarily install companion flange on end of pinion

correct assembly. After reassembly, torque case bolts

shaft without installing pinion oil seal retainer. install

and lockwire bolts in pairs as shown in Fig. 106.

companion flange retaining tool on companion flange

using spacers shown in Fig. 30 and socket shown in

Fig. 31. Torque companion Range nut to 600 ft. Ibs.

(Fig. 120).

FIG. 118

TS-6232

Reassembly of Differential and Carrier

1. Install bearing cage and pinion shaft assembly in dif-

ferential carrier assembly, using original shim pack or

[38]