TM 5-3805-258-24-1

950B

POWER

TRAIN

S P E C I F I C A T I O N S

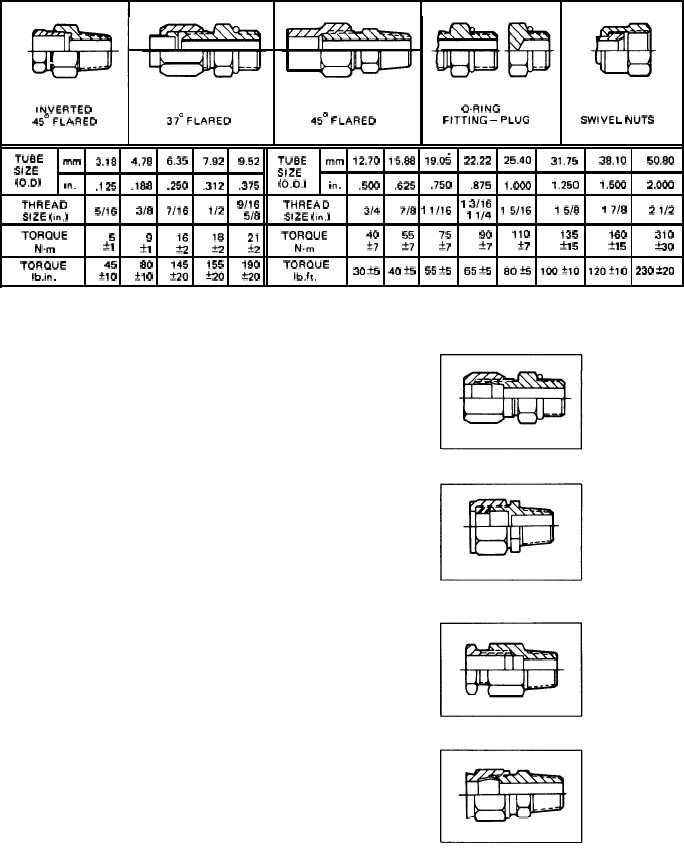

INVERTED

O-RING

45° FLARED

37° FLARED

45° FLARED

FITTING – PLUG

SWIVEL NUTS

TUBE

fn~

3.18

4.78

6.35

7.92

9.52

TUBE

mm

12.70

15.88

19.05

22.22

25.40

SIZE

31.75

38.10

50.80

SIZE

(0.D)

In,

.125

.166

.250

.312

.375

(0. D.)

in.

.500

.625

.750

.875

1.000

1.250

1.500

2.000

THREAD

5/16

318

7116

,,2

9116

THREAD

3/4

1

3/16

SIZE (in.)

5/8

718

1

1/16

, ,,4

15116

1518

1

7/8

SIZE (In.)

2112

TORQUE

5

9

21

TORQUE

40

55

75

90

110

135

160

310

N.m

fl

tl

;

z

*2

N.m

*7

?7

*7

?7

*7

tl 5

fl 5

tio

TORQUE

45

80

145

155

190

TORQUE

Ib.in.

*1O

tl o

?20

30

%0

Ib.ft.

30 s

40

?5

55

*5

65

*5

80%

100*1O

120~lo

230

~20

TORQUES FOR 0THER FITTINGS

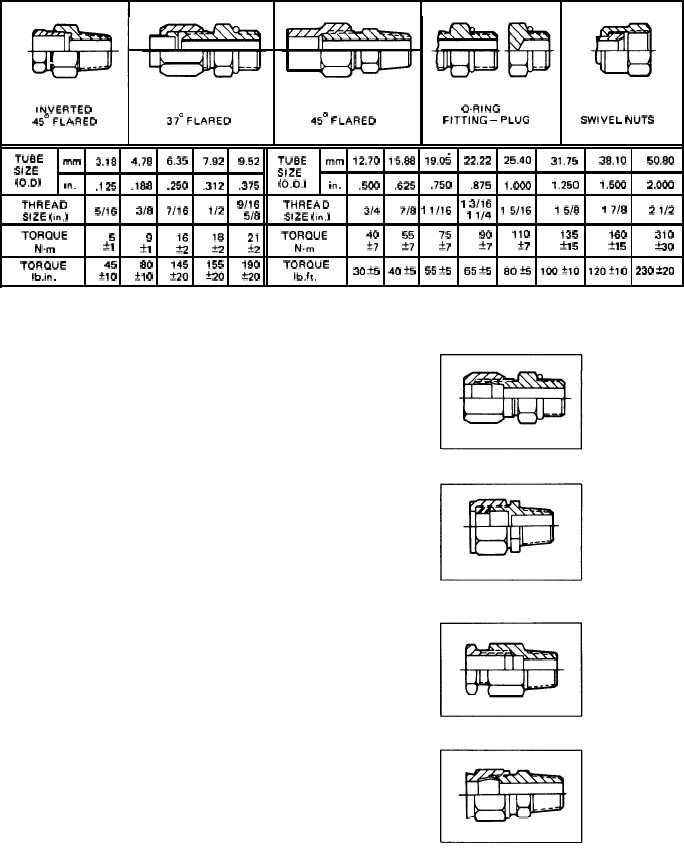

Ermeto Tube Fittings

Put nut and sleeve over the tube with head or shoulder end

of sleeve next to nut. Push tube into counterbore of fitting

body as far as possible. Turn nut clockwise until sleeve holds

tube and prevents movement. Tighten the nut 1¼ turns more

to seat sleeve and give a locking action. When necessary to

assemble again, put sleeve over tube and tighten nut until a

sudden increase in torque is felt. Then tighten 1/6 to 1/3 turn

more to seat the sleeve.

Flex Fittings

Put nut and sleeve over tubing and push tube into

counterbore of fitting body as far as possible. Tighten the nut

until it is against the hex part of the fitting body.

Hi Duty (shear sleeve)

Tube Fittings

After tube has been put through the nut and makes

contact against the tube shoulder in the fitting body, turn the

nut with a wrench until a small decrease in torque is felt. This

is an indication that the sleeve has been broken off of the

nut. Hold the tube to prevent turning and tighten the nut 1

and 1/2 turns.

Hi Seal Fittings

Put nut and sleeve over the tubing with the short heavy

end of the sleeve facing the end of tubing. Put the tube end

against the counterbore in the body of the fitting and tighten

until nut is over the last thread on the body. The remainder

of space is used whenever the fitting is removed and installed

again

A 2 9 9 2 0 X 2

2-77/2-78 (blank)