TM 5-3805-258-24-1

ENGINE

FUEL SYSTEM

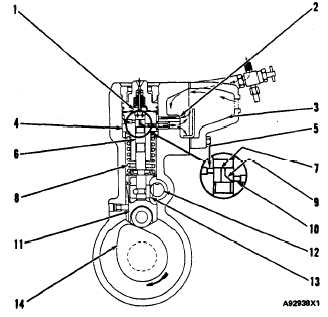

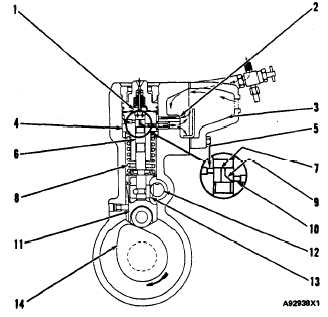

When the pump plunger is at the bottom of the

stroke, fuel at transfer pump pressure goes into inlet

passage (2), around pump barrel (4) and to bypass

closed port (5). Fuel fills the area above the pump

plunger.

After the pump plunger begins the up stroke, fuel

will be pushed out the bypass closed port until the top

of the pump plunger closes the port. As the pump

plunger travels farther up, the pressure of the fuel

increases. At approximately 690 kPa (100 psi),

check valve (1) opens and lets fuel flow into the fuel

injection line to the fuel injection nozzle. When the

pump plunger travels farther up, scroll (9) uncovers

spill port (10). The fuel above the pump plunger goes

through slot (7), along the edge of scroll (9) and out

spill port (10) back to fuel manifold (3). This is the

end of the injection stroke. The pump plunger can

have more travel up, but no more fuel will be sent to

the fuel injection nozzle.

FUEL INJECTION PUMP

1 . C h e c k v a l v e . 2 . I n l e t p a s s a g e . 3 . F u e l m a n i f o l d . 4 .

Pump barrel. 5. Bypass closed port. 6. Pump plunger. 7.

Slot. 8. Spring. 9. Scroll. 10. Spill port. 11. Lifter. 12. Fuel

rack. 13. Gear. 14. Cam.

When the pump plunger travels down and un-

covers bypass closed port (5), fuel begins to fill the

area above the pump plunger again, and the pump is

ready to begin another stroke.

The amount of fuel the injection pump sends to the

injection nozzle is changed by the rotation of the

pump plunger. Gear (13) is attached to the pump

plunger and is in mesh with fuel rack (12). The

governor moves the fuel rack according to the fuel

needs of the engine. When the governor moves the

fuel rack, and the fuel rack turns the pump plunger,

SYSTEMS OPERATION

scroll (9) changes the distance the pump plunger

pushes fuel between bypass closed port (5) and spill

port (10) opening. The longer the distance from the

top of the pump plunger to the point where scroll (9)

uncovers spill port (10), the more fuel will be

injected.

To stop the engine, the pump plunger is rotated so

that slot (7) on the pump plunger is in line with spill

port (10). The fuel will now go out the spill port and

not to the injection nozzle.

FUEL INJECTION NOZZLE

The fuel injection nozzle goes through the cylinder

head into the combustion chamber. The fuel injec-

tion pump sends fuel with high pressure to the fuel

injection nozzle where the fuel is made into a fine

spray for good combustion.

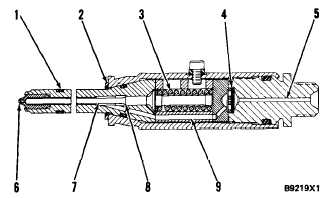

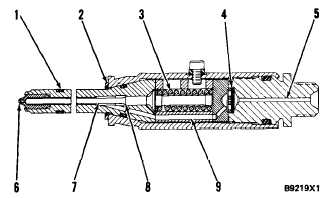

FUEL INJECTION NOZZLE

1. Carbon dam. 2. Seal. 3. Spring. 4. Filter screen. 5. Inlet

passage. 6. Orifice. 7. Valve. 8. Diameter. 9. Passage.

Seal (2) goes against the cylinder head and pre-

vents leakage of compression from the cylinder. Car-

bon dam (1) keeps carbon out of the bore in the

cylinder head for the nozzle.

Fuel with high pressure from the fuel injection

pump goes into inlet passage (5). Fuel then goes

through filter screen (4) and into passage (9) to the

area below diameter (8) of valve (7). When the pres-

sure of the fuel that pushes against diameter (8)

becomes greater than the force of spring (3), valve

(7) lifts up. When valve (7) lifts, the tip of the valve

comes off of the nozzle seat and the fuel will go

through the nine 0.20 mm (.008 in.) orifices (6) into

the combustion chamber.

The injection of fuel continues until the pressure of

fuel against diameter (8) becomes less than the force

of spring (3). With less pressure against diameter

(8), spring (3) pushes valve (7) against the nozzle

seat and stops the flow of fuel to the combustion

chamber.

3-4