TM 5-3805-258-24-1

P O W E R T R A IN

T R A N S M I S S I O N H Y D R A U L I C S Y S T E M

S Y S T E M S O P E R A T I O N

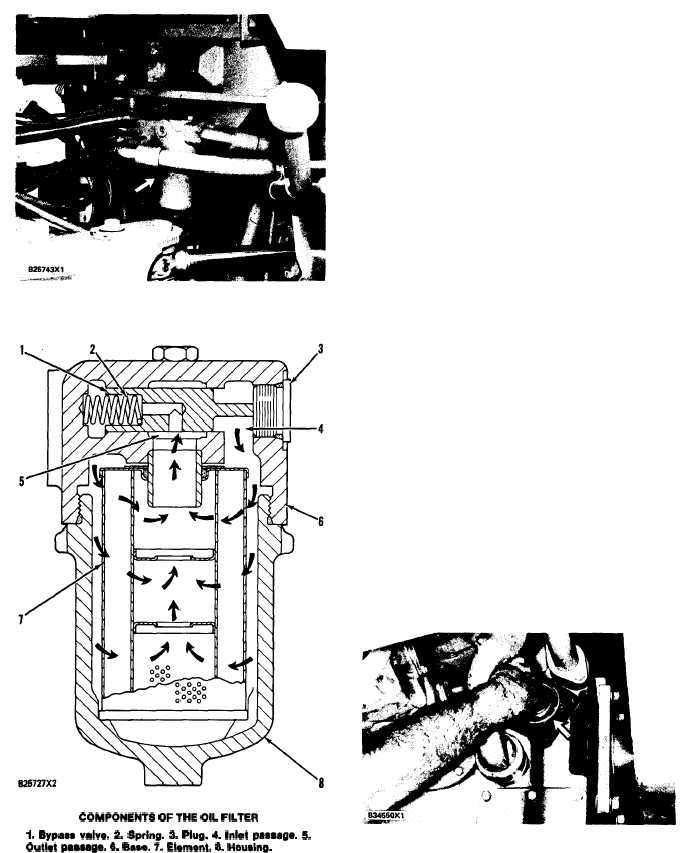

OIL FILTER

Pressure oil, from the oil pump, goes in filter base

(6) through inlet passage (4). The oil goes through

the filter base to housing (8). Oil fills the space

between the inside of housing (8) and filter element

(7). Normally, oil goes through the filter element and

then to the outlet passage. The oil then goes to the

remainder of the hydraulic system. The filter ele-

ment stops any debris that is in the oil.

If the filter element becomes full of debris, the

restriction to the flow of oil causes a pressure increase

inside the filter. The increase in pressure causes by-

pass valve (1) to open. The oil then goes to the

hydraulic system. When the oil does not go through

the filter element, it is dirty and the debris in the oil

can cause damage to other components in the hy-

draulic system.

Correct maintenance must be used to make certain

that filter element (7) does not become full of debris

LOCATION OF OIL FILTER

and stop the flow of clean oil to the hydraulic system.

MAGNETIC SCREEN

A magnetic screen is inside of the transfer gear

case. Oil from the bottom of the transfer gear case

goes through an inlet passage. As the oil goes through

the screen, foreign particles that are in the oil are

stopped by the screen and can not go into the trans-

mission hydraulic system.

After the oil goes through the screen, it goes

around and through magnets. The magnets are in-

stalled on the tube assembly so that the same magne-

tic ends are next to each other. Smaller metal parti-

cles that go through the screen are stopped and held

by the magnets. These magnets will not let the metal

particles go with the oil through the hydraulic

system.

The oil then goes through the outlet passage to the

transmission pump.

COMPONENTS OF THE OIL FILTER

1. Bypass valve. 2. Spring. 3. Plug, 4. Inlet passege. 5.

Outlet pemege. 6. Base. 7. Etement. 8. Housing.

LOCATION OF MAGNETIC SCREEN

3-28