TM 5-3805-258-24-1

S T E E R I N G S Y S T E M

S U P P L E M E N T A L S T E E R I N G S Y S T E M

The main components for the supplemental steer-

ing system are: supplemental steering pump (18),

diverter valve (17) and flow switch (16).

The supplemental steering pump is a ground dri-

ven pump; it is turned as long as the machine moves.

The pump gets its power from the output transfer

gears of the transmission.

When the engine is running, primary steering

pump section (7) sends oil through diverter valve

(17) to steering control valve (9). This oil is used to

operate the steering cylinders.

As soon as the machine starts to move, oil is also

sent from supplemental steering pump (18) to the

diverter valve. When the machine moves and the

engine rpm is less than 1450 ± 150 rpm, the oil from

the supplemental steering pump and primary steer-

ing pump section is combined (flows together) in

the diverter valve. This oil flows from the diverter

valve to the steering control valve.

When the machine moves and the engine rpm is

more than 1450 ± 150 rpm, the diverter valve sends

the oil from the supplemental pump back to the

hydraulic tank. The oil supply for the steering con-

trol valve will then come only from the primary

steering pump section. If, under this condition,

there is a primary steering pump failure, the diver-

ter valve will immediately send the oil from the

supplemental pump back to the steering control

valve.

Flow switch ( 16) is installed on the elbow for the

primary steering pump section. It is shown on the

schematic between the primary steering pump sec-

tion and diverter valve. This flow switch warns the

operator of a failure of the primary steering pump

section or lines.

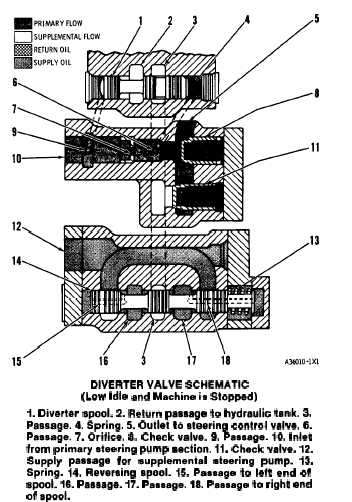

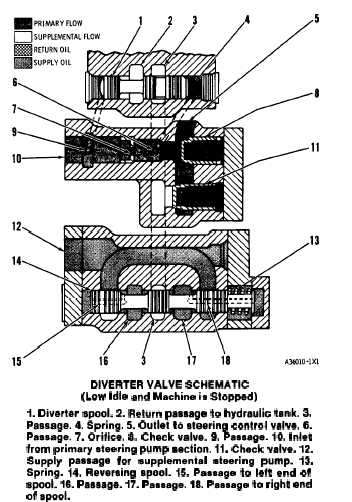

DIVERTER VALVE

The main components of the diverter valve are:

diverter spool (1), check valves (8) and (11), and

reversing spool (14).

When the engine is running, the oil from the pri-

mary steering pump section goes through inlet (10)

and orifice (7) to check valve (8). The force of the oil

opens the check valve. The oil flows past the check

valve, and through outlet (5) to the steering control

valve. Check valve (11) will not let the primary oil

flow into passage (3).

The pressure of the oil before orifice (7) is more

than the pressure of the oil after the orifice. These

pressures are also felt through passage (9) and (6)

respectively.

S Y S T E M S O P E R A T I O N

DIVERTER VALVE SCHEMATIC

(Low Idle and Machina ia Stopped)

1. Diverter spool. 2. Return paasage to hydraulic tank. 3.

Passage. 4. Spring. 5. Outlet to steering control valve. 6.

Paasage. 7. Orifice. 6. Check valve. 9. Paasage. 10. Inlet

from primary steering pump section. 11. Check valve. 12.

Supply paasage for supplemental steering pump. 13.

Spring. 14. Reversing spool. 15. Paeaage to left end of

spool. 16. Paasage. 17. Paasage. 18. Paaaage to right and

of spool.

The pressure of the oil is the same before the

orifice and to the left end of diverter spool (1). The

pressure of the oil after the orifice is the same as the

pressure of the oil to the right end of the spool.

As the engine rpm increases, the flow from the

primary steering pump section increases also. Be-

cause of this increased flow past orifice (7), there

is an increase in the difference of the oil pressure

before and after the orifice. When the force of the

oil on the left end of the spool is more than the total

force of the oil and the spring on the right end, the

diverter spool will move to the right. This takes

place when the engine rpm is 1450 ± 150 rpm.

There is no oil sent from the supplemental steering

pump until the machine moves. When the machine

moves, the pump is turned by the output transfer

gears. Oil from the hydraulic tank is supplied to the

supplemental pump through passage (12). Oil flows

from the hydraulic tank through passage (12), to

reversing spool (14).

When the machine moves in a forward direction,

the supplemental pump sends pressure oil into pas-

sage (17). The pressure of this oil is felt through

3-68