TM 5-3805-258-24-1

S T E E R I N G S Y S T EM

S U P P L E M E N T A L S T E E R I N G S Y S T EM

S Y S T E M S

O P E R A T I O N

passage (18) to the right end of reversing spool (14).

The force of this oil moves the reversing spool to the

left. Oil from the supplemental pump can then flow

from passage (17) into passage (3). Passage (3) takes

the oil to check valve (11) and diverter spool (1).

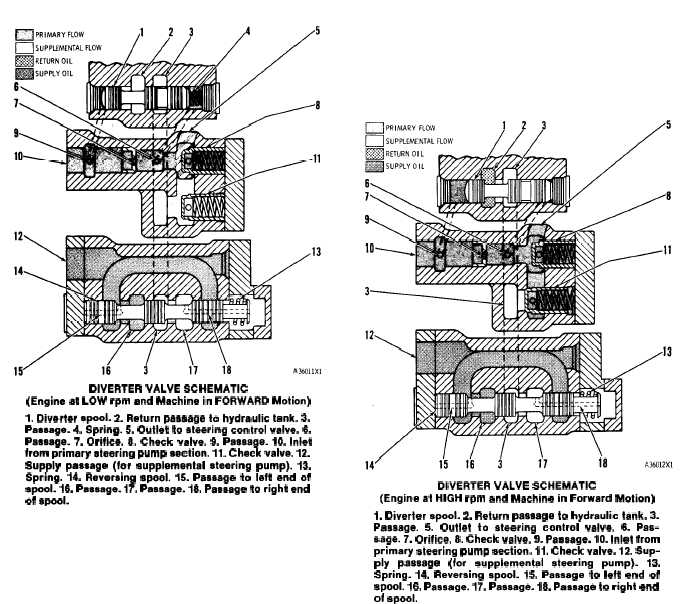

If the engine rpm is low, the diverter spool will be

to the left. Oil flow past the diverter spool is stopped.

The pressure of the oil in passage (3) increases until

check valve (11) opens. This lets the oil from the

supplemental pump flow past check valve (11) to

check valve (8). The oil then flows together with the

oil from the primary system and goes through outlet

(5). This combined flow of oil then goes to the steer-

ing control valve.

DIVERTER VALVE SCHEMATIC

(Engine at LOW rpm end Machine in FORWARD Motion)

1. Diverter spool. 2. Return passage to hydraulic tank. 3.

Paasage. 4. Spring. 5. Outlet to steering control valve. 6.

Paaaage. 7. Orifice. 8. Check valve. 9. Passage. 10. Inlet

from primary steering pump section. 11. Check valve. 12.

Supply paasage (for supplemental steering pump). 13.

Spring. 14. Reversing spool. 15. Passaga to left end of

spool. 16. Pasaage. 17. Paaaage. 18. Passage to right end

of spool.

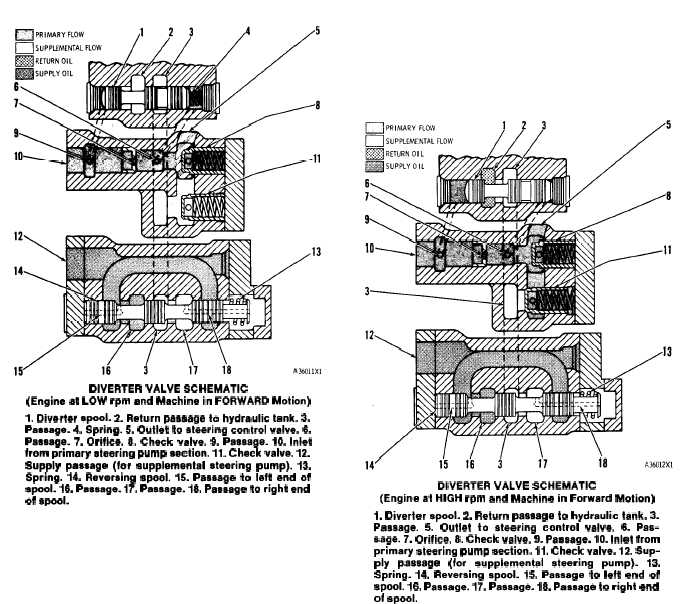

If the engine rpm is high, diverter spool (1) will be

to the right. The oil from the supplemental pump

flows into passage (3). The oil flows around spool (1),

into passage (2), and back to the hydraulic tank.

Only the primary pump flow is sent to the steering

control valve through outlet (5). Check valve (11)

will not let the primary oil flow into passage (3).

If there is a failure of the primary steering pump

section, or if the engine stops there will be a loss of

primary flow. Diverter spool (1) will move to the left.

As long as the machine moves, the flow from the

supplemental pump will provide the oil for the steer-

ing operation. The oil will flow through passage (3),

past check valve (11), and through outlet (5). Check

valve (8) will prevent the loss of flow through inlet

(10), and the stopped primary pump.

When the machine moves in a reverse direction,

the supplemental pump turns in the opposite direc-

tion. The pressure oil from the pump is sent through

passages (16) and (15) to the left end of reversing

spool (14). This causes the spool to move to the right.

The pressure oil can then flow through passage (16)

into passage (3). The rest of the oil flow is the same as

when the machine moves forward.

DIVERTER VALVE SCHEMATIC

(Engine at HIGH rpm and Machine in Forward Motion)

1. Diverter spool. 2. Return passage to hydraulic tank. 3.

Passage. 5. Outlet to atearing control valve. 6. Pas-

sage. 7. Orifice. 8. Check valva. 9. Passage. 10. Inlet from

primary steering pump section. 11. Check valve. 12. Sup-

ply

passage

(for

supplemental

steering

pump).

13.

Spring. 14. Reversing spool. 15. Passage to left end of

spool. 16. Passage. 17. Passage. 18. Passage to right end

of spool.

3-69