S I N G L E

C Y L I N D E R

A l R C O M P R E S S O R

TM 5-3805-258-24-1

S Y S T E M S

O P E R A T I O N

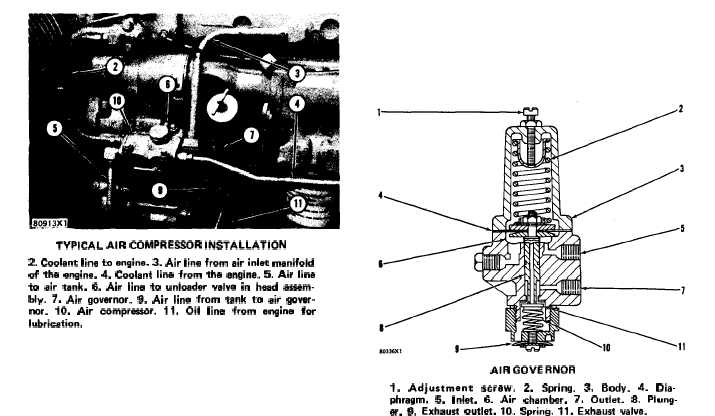

TYPICAL AIR COMPRESSOR INSTALLATION

2. Coolant line to engine. 3. Air line from air inlet manifold

of the engine. 4. Coolant line from the angine. 5. Air line

to air tank. 6. Air Iina to unloader valve in haad aaaam-

bly. 7. Air governor. 9. Air line from tank to air govar-

nor. 10. Air compressor. 11. Oil line from engine for

lubrication.

Components connected to the air line (13) from

the air tank (1) use the air in the tank and the

pressure of the air gets a decrease. When the pres-

sure of the air (getting less and less) gets to the cut

in pressure setting of the air governor, the plunger

in the air governor closes. Now the air from the

line (9) can not go through the line (6) to the

unloader valve in the head assembly. The air goes

out of the line (6) and the unloader valve moves

away from the inlet valve. The inlet valve can again

open and close with the movement of the piston.

Air from the air compressor (10) now goes to the

air tank (1).

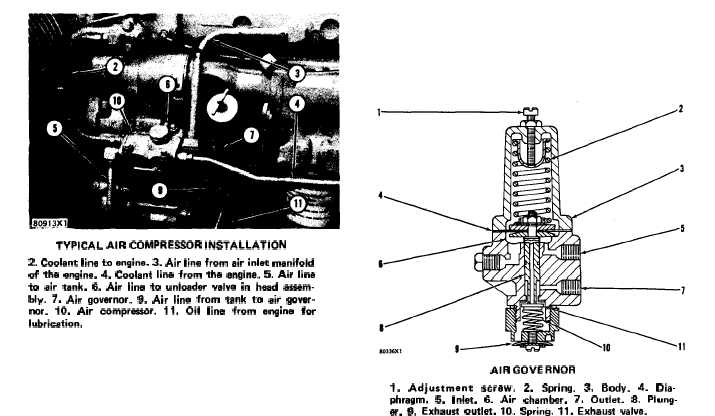

AIR GOVERNOR

NOTE: On models 950BSCE and 950BNSCE the

air governor is located on top of the air compressor

instead of the back.

A line from the air tank is connected to inlet (5)

of the air governor. The pressure of the air in inlet

(5) and in chamber (6) is the same as the pressure

of the air in the tank. The air in inlet (5) also goes

into an air passage in plunger (8). Spring (10) holds

exhaust valve (11) against the opening in the end

of the air passage and the air can not get out of

plunger (8).

As the air compressor puts more air into the

tank the pressure of the air in the tank and also in

chamber (6) gets an increase. The pressure of the

air in chamber (6) moves diaphragm (4) against the

force of spring (2). The diaphragm also moves

plunger (8). Spring (10) keeps the exhaust valve

(11) against the plunger as it moves. The cut out

pressure setting of the air governor is when the

pressure of the air in chamber (6) has moved dia-

phragm (4) and plunger (8) until spring (10) moves

exhaust valve (11) against the seat in body (3) and

the air passage in the end of the plunger is open.

Now the air from the tank goes through inlet (5),

through the air passage in plunger (8) and through

outlet (7) to the unloader valve in the cylinder

head of the air compressor.

AIR GOVERNOR

1.

Adjustment

straw.

2.

Spring.

3.

Body.

4.

Dia-

phragm. 5. Inlat. 6. Air chamber. 7. Outlet. 8. Plung-

er. 9. Exhaust outlet. 10. Spring. 11. Exhaust valve.

When the air in the tank is used, the pressure of

the air in the tank gets a decrease. Now spring (2)

moves diaphragm (4) and plunger (8). The cut in

pressure is when the pressure of the air in the tank

and in chamber (6) is less than the force of spring

(2) and the spring moves plunger (8) far enough to

move exhaust valve (11) away from the seat in

body (3). Now the air from the unloader valve goes

into outlet (7) and through exhaust outlet (9) and

the unloader valve lets the inlet valve for the air

compressor operate.

Adjustment screw (1) can be turned to either

make an increase or a decrease in the cut out pres-

sure setting of the air governor. The cut in pressure

is always approximately 15 psi (1.05 kg/cm2) less

than the cut out pressure setting.

AIR COMPRESSOR LUBRICATION

An oil line from the engine lubricating oil sys-

tem is connected to opening (1) in the end cover of

the air compressor.

Pressure oil from opening (1) goes through an

opening in the bearing and the main journal of the

crankshaft gets lubrication. The oil goes through

opening (5) in the main bearing journal, through a

passage in the crankshaft and through opening (4)

in the rod bearing journal. With the oil going out

through opening (4) and running out between the

3-127