E L E C T R I C A L

S Y S T E M

TM 5-3805-258-24-1

T E S T I N G

A N D

A D J U S T I N G

2.

3.

4.

Cables between the battery, starter and engine

ground must be the correct size. Wires and ca-

bles must be free of corrosion and have cable

supports clamps to prevent stress on battery con-

nections (terminals).

Leads, junctions, switches and panel instru-

ments that have direct relation to the charging

circuit must give correct circuit control.

Inspect the drive components for the charging

unit to be sure they are free of grease and oil and

have the ability to operate the charging unit.

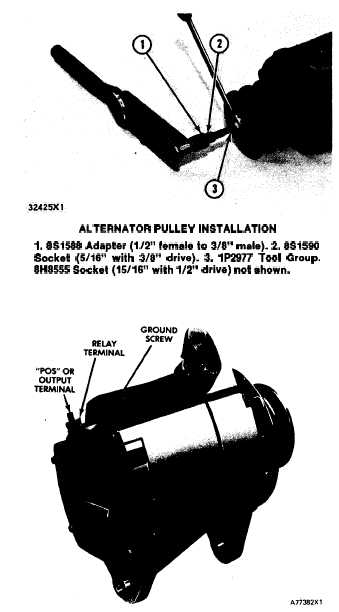

Delco-Remy Alternator; Pulley Nut Tightening

Tighten nut holding the pulley to a torque of 100

± 7 N·m (75 ± 5 lb. ft. ) with the tools shown.

ALTERNATOR PULLEY INSTALLATION

1. 8S1566 Adapter (1/2” female to 3/8” male). 2. 8S1590

Socket (5/18” with 318” drive). 3. IP29?7 Tool Group.

8H8555 Sockat (15/16” with 112” drive) not shown.

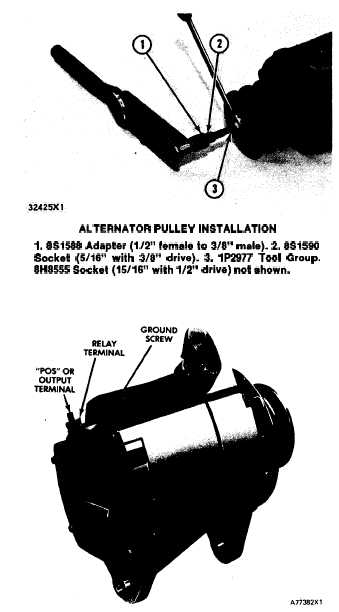

Delco-Remy 24V 50A (3T1888 Alternator)

6 N 9 2 8 4 A L T E R N A T OR

No adjustment can be made to change the rate of

charge on this alternator regulator. If rate of charge

is not correct, a replacement of the regulator is

necessary.

STARTING SYSTEM

T o o l s

N e e d e d :

5 P 3 0 0

E l e c t r i c a l

T e s t e r .

NOTE: Make reference to Special Instruction Form

No. SEHS7006 and to the instructions inside of the

cover of the tester, when testing with the 5P300

Electrical Tester.

Use a D.C. Voltmeter to find starting system com-

ponents which do not function.

Move the starting control switch to activate the

starter solenoid. Starter solenoid operation can be

heard as the pinion of the starter motor is engaged

with the ring gear on the engine flywheel. The solen-

oid operation also closes the electric circuit to the

motor. Connect one wire of the voltmeter to the

solenoid connection (terminal) that is fastened to the

motor. Connect the other wire to a good ground.

Activate the starter solenoid and look at the volt-

meter. A reading of battery voltage shows the prob-

lem is in the motor. The motor must be removed for

more testing. No reading on the voltmeter shows that

the solenoid contacts do not close. This is an indica-

tion of the need for repair to the solenoid or of an

adjustment to be made to starter pinion clearance.

If the solenoid for the starter motor will not oper-

ate, current from the battery may not be getting to

the solenoid. Fasten one wire of the voltmeter to the

connection (terminal) for the battery cable on the

solenoid. Connect the other wire to a good ground.

No voltmeter reading shows there is a break in the

circuit from the battery. More testing is necessary

when there is a reading on the voltmeter

Now make a test by fastening one voltmeter wire

to the connector (terminal) for the small wire at the

solenoid and the other wire to a ground. Look at the

voltmeter and activate the starter solenoid. A volt-

meter reading shows that the problem is in the solen-

oid. No voltmeter reading shows that the problem is

in the starter switch or wiring. Fasten one wire of the

voltmeter to the battery wire connection of the

starter switch and the other wire to a ground. A

voltmeter reading shows a failure in the switch.

A starter motor that operates too slowly can have

an overload because of too much friction in the en-

gine being started. Slow operation of the starter mo-

tor can also be caused by shorts, loose connections

and/or dirt in the motor.

4-41