TM 5-3805-258-24-2

ENGINE

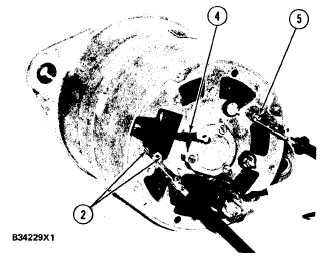

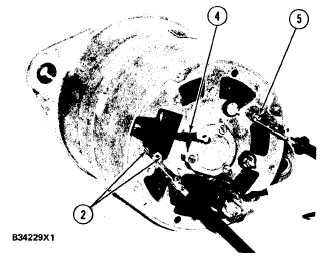

Winding To Frame Test

Connect ohmmeter between the (B–) terminal and

each of the two field coil winding leads (2). Each of

the two readings should be high (indicating no shorts

to frame).

POLE BODY WINDING TO FRAME TEST

2. Field winding leads. 4. Rectifier bridge lead. 5. Terminal

( B - ) .

Stator Test

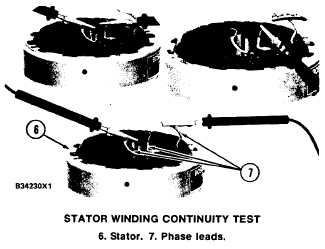

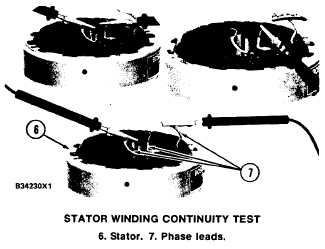

Stator Winding Continuity Test

TESTING

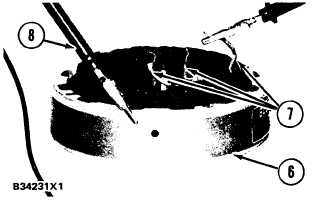

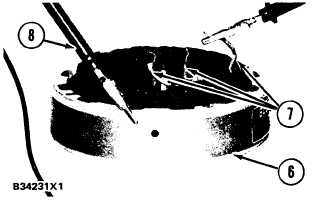

Stator Winding to Frame Test

Connect the ohmmeter between each of the three

stator windings and the frame (three readings). Re-

sistance values should be very high (an indication of

no shorts to frame).

STATOR WINDING TO FRAME TEST

(Test Other Two Leads As Shown)

6. Stator. 7. Phase leads. 8. Test lead to frame.

Rectifier Test

Unsolder stator winding leads (7) from rectifier and

remove stator (6). Disconnect capacitor lead from

(D+) terminal. On the ohmmeter checks that fol-

low, make one check then reverse the ohmmeter

leads. One reading should be high and one low. If not,

the rectifier has a defect and should be replaced.

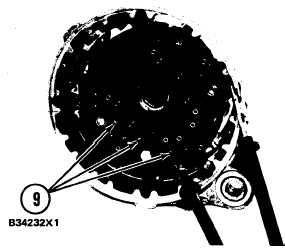

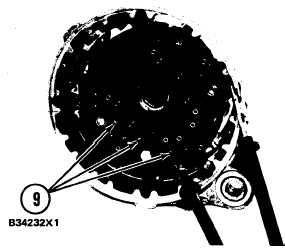

Minus Diode Check

Connect ohmmeter between each rectifier solder

phase terminal (9) and the frame (ground).

Remove stator (6) from frame assembly. Connect

ohmmeter between pairs of the three stator winding

leads (7) (three readings). Resistance should be .15

to .25 ohms.

If the resistance test values are not correct, then the

stator (6) has a defect.

MINUS DIODE CHECK

9. Bridge rectifier terminals.

5-12h