POWER TRAIN

TRANSFER

GEARS

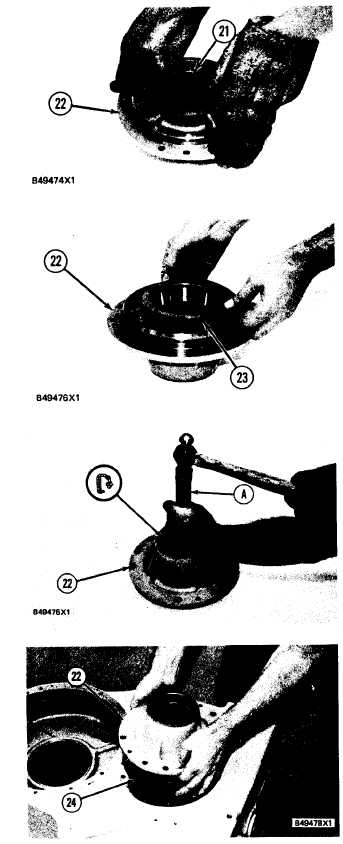

21.

22.

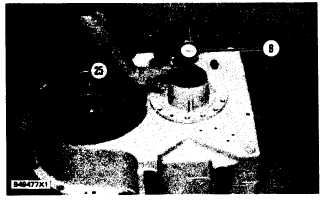

23.

Lower the temperature of bearing cup (21) and

install it in cage (22).

Install O-ring seal (23) on cage (22).

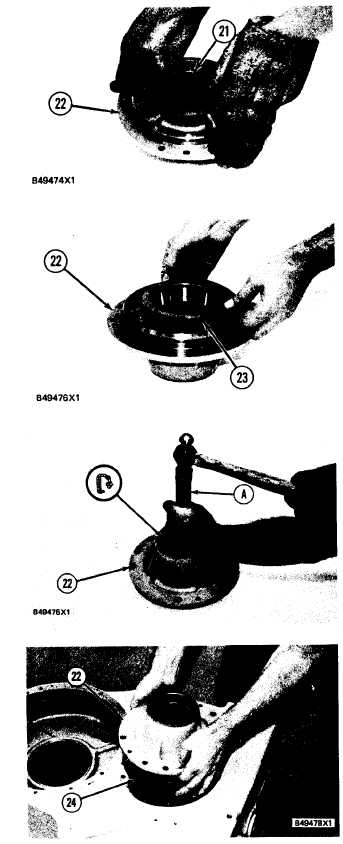

Put 7M7260 Liquid Gasket Material in the

seal bore in cage (22) and let it dry, Do not put

the liquid gasket material on the lip of the seal

case. Use tooling (A) and install the seal in cage

(22) with the lip of the seal toward the inside as

shown. Put clean power train oil on the lip of

the seal.

TM 5-3805-258-24-2

DISASSEMBLY AND ASSEMBLY

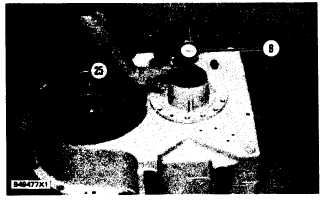

24. The bearing axis must be in a vertical position

for the correct bearing adjustment.

25.

26.

Install original shims (24) and cage (22) on the

case.

Use tool (B) and a pry bar (25) to check bear-

ing end play. Add or remove shims to get a

bearing end play of 0.05 to 0.15 mm (.002 to

.006 in.).

5-309