TM 5-3805-262-20

11-1. BUCKET TILT CYLINDER ASSEMBLIES MAINTENANCE (CONT)

b. Replacement.

This task covers removal and installation of bucket tilt cylin-

der assemblies.

TOOLS: No. 1 Common Organizational Maintenance Tool Kit

Safety glasses

Hand hammer, three pounds

Lubricating unit

Combination box and open end wrench set

Torque wrench, 3/4 inch drive

Vise

S l i p j o i n t p l i e rs

Long nose pliers

Automotive Mechanic’s Tool Kit

Socket wrench set, 1/2 inch drive

No. 2 Common Organizational Maintenance Tool Kit

Adapter, socket wrench, 1/2 inch male to 3/4 inch female

Pry bar

Chain hoist equipped with nylon straps

Rod, 1-7/8 inches diameter by eight inches long

Acetylene torch

Wood block, 3/4 inch square

Insulated gloves

Wood block, 2 by 4 by 4 inches long

Torque wrench multiplier, 2000 lb-ft capacity

MATERIALS/PARTS: Loctite 242 (blue) (Appendix C, item 18)

Tie straps, quantity as required (FSCM 53421 PN T50ROW)

Retaining rings, two (FSCM 10988 PN L16015)

O-rings, four (FSCM 10988 PN 218-5010)

clamps, two (FSCM 10988 PN 214-273)

REFERENCE: LO 5-3805-262-12

NOTE

PRELIMINARY PROCEDURE: Front access door open and hydraulic reservoir

fill cap loosened. Control levers operated in both directions to relieve

hydraulic pressure. Return-to-dig control removed from right bucket tilt

cylinder assembly (page 11-12).

REMOVAL (SHEET 1 OF 5)

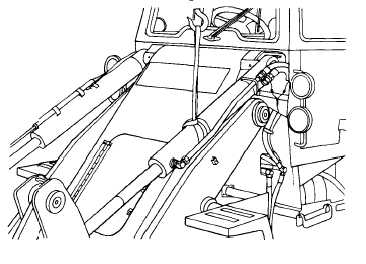

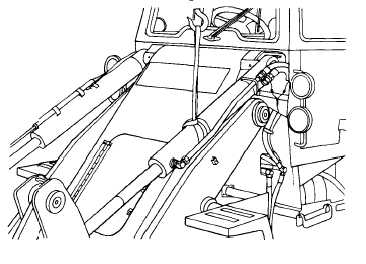

(1) Attach chain hoist equipped with

n y l o n s t r a p t o b u c k e t t i l t c y l-

inder assembly as shown; take up

a l l s l a c k .

11-4