TM 5-3805-262-20

3-19. AIR BRAKE SYSTEM TROUBLESHOOTING (CONT)

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

3. LOW AIR PRESSURE (AIR PRESSURE GAGE INDICATES IN RED ZONE AND LOW AIR PRES-

SURE BUZZER SOUNDS) (Cont).

Step 6.

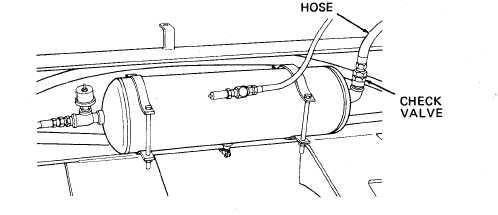

Disconnect hose connected to check valve.

Remove check valve from elbow.

Connect an air hose connected to a regulated air supply capable

supplying up to 160 psi air pressure to check valve female end.

of

Apply air pressure to check valve; check valve shall not v e n t a i r.

a. If check valve vents air, replace it (page 7-58).

b. If check valve does not vent air, reinstall it and connect hose

to check valve. Go to step 7 below.

Step 7.

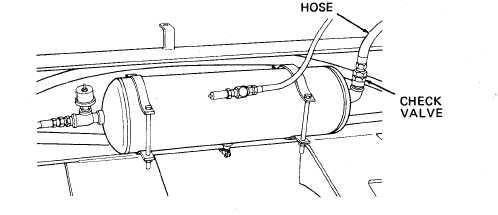

Close air reservoir drain valve.

T e l l a s s i s t a n t t o s t a r t e n g i n e.

W i t h e n g i n e o p e r a t i n g , i n s p e c t a i r r e s e r v o i r , f i t t i n g s , a n d h o s es

for air leakage (page 7-56).

a. If a hose is leaking, replace (page 7-58).

b . I f a f i t t i n g i s l e a k i n g , t i g h t e n i t ; i f i t s t i l l l e a k s a f t e r

t i g h t e n i n g , r e p l a c e i t ( p a g e 7 - 5 8 ).

c . I f a i r r e s e r v o i r i s d a m a g e d , r e p l a c e i t ( p a g e 7 - 5 8 ).

d. If fittings and hoses are okay, go to step 8 below.

Step 8.

With engine operating, inspect air compressor lines for air leakage

(page 7-102).

a. If air compressor lines are leaking tighten; if tightening does

no good, replace leaking lines (page 7-106).

b. If air compressor lines are okay, go to step 9 below.

3-123