TM 5-3805-262-20

3-25. HYDRAULIC SYSTEM TROUBLESHOOTING (CONT)

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

6. LIFT CYLINDER ASSEMBLIES OPERATING SLUGGISHLY OR POORLY (ALL OTHER CYLINDERS

OPERATING OKAY ) (Cont).

S t e p 4 . ( C o n t ).

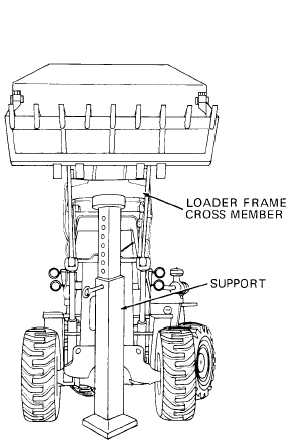

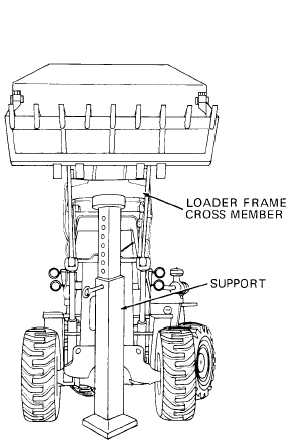

Place a support below loader

frame cross member to hold

loader frame in position.

Operate control levers several

times to relieve hydraulic

system pressure.

Hydraulic system pressure is over

20 0 0 p s i a n d h y d r a u l i c r e s e r v o ir

i s p r e s s u r i z e d w i t h c o m p r e s s e d

a i r . B e f o r e l o o s e n i n g o r

d i s c o n n e c t i n g a n y h y d r a u l i c

h o s e s , l i n e s , o r f i t t i n g s , l o o s e n

h y d r a u l i c r e s e r v o i r f i l l c a p , a n d

o p e r a t e a l l h y d r a u l i c c o n t r o l

l e v e r s t o r e l i e v e h y d r a u l i c

system pressure. Failure to do so

c o u l d c a u s e s e r i o u s i n j u r y o r

death .

I f y o u a r e i n j u r e d o b t a in

medical assistance immediately.

Disconnect hose connected to

rod end of each lift cylinder

assembly from tube that comes

through side of loader front

c h a s s i s.

Install a cap on each tube.

S t a r t e n g i n e - a n d o p e r a t e a t f u l l t h r o t t l e.

Hold LIFT ARM control lever in RAISE position and tell assistant to

check for hydraulic oil leakage at each hose disconnected above.

a. If there is constant leakage from a hose, the cylinder packing

is damaged. Shut off engine and replace lift cylinder assembly

connected to hose which was constantly leaking (page 11-65).

b. If there wasn’t constant leakage from a hose, notify next higher

maintenance level to replace control valve assembly.

3-190