TM 5-3805-262-20

4-2. FUEL SYSTEM MAINTENANCE (CONT)

g. C o l d S t a r t K i t ( c o n t ) .

INSPECTION

NOTE

In following steps, replace parts determined to be defective.

( 1 ) C h e c k b a i l ( 2 ) a n d e x t e n s i o n l i n k s ( 3 ) f o r c r a c k s , b e n t c o n d i t i o n , or

o t h e r d e f e c t s.

( 2 ) C h e c k t u b e ( 7 ) f o r c r a c k s , b r e a k s , o r d e t e r i o r a t i o n . I f t u b e r e q u i r e s r e -

placement, remove compression nuts (5) and compression sleeves (6) then

d i s c a r d t u b e ( 7 ).

Compressed air used for cleaning purposes will not exceed 30 psi. Use

o n l y w i t h e f f e c t i v e c h i p g u a r d i n g a n d p e r s o n a l p r o t e c t i v e e q u i p m e nt

( g o g g l e s / s h i e l d , g l o v e s , e t c ) . F a i l u r e t o d o s o c o u l d c a u s e s e r i o us

i n j u r y t o e y e s a n d p o s s i b l e b l i n d n e s s .

If you hurt your eyes or if a

f o r e i g n o b j e c t i s b l o w n i n t o y o u r e y e s , s e e k m e d i c a l a t t e n t i o n

immediately.

(3)

( 4)

(5)

(6)

4-52

Check nozzle (8) and fitting (9) for clogged condition; use compressed

air to clear blockage. Check for cracks, breaks, or damaged threads.

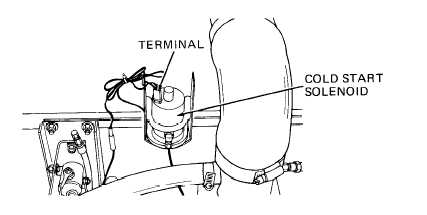

Check solenoid (16) for cracked body, loose or corroded terminals, or

other damage. Connect multimeter between solenoid terminals; multimeter

should indicate continuity. If multimeter indicates no continuity, re-

place solenoid.

Check wiring for frayed or cracked insulation; repair using insulation

tape applied to damaged area.

Check remaining parts for cracks, breaks, distortion, or damaged threads.