TM 5-3805-262-20

7-3. AIR BRAKE SYSTEM MAINTENANCE (CONT)

g. Air Compressor Assembly (cont).

(2) Air Compressor Drive Belt.

This task covers removal, installation, and ad-

justment of air compressor drive belt. Drive belt tension shall be checked after

every 500 hours of operation.

If a new drive belt is installed, check tension after

first 20 hours of operation then again after every 500 hours of operation.

TOOLS: No. 1 Common Organizational Maintenance Tool Kit

Socket wrench set, 3/8 inch drive

Belt tension gage

MATERIALS/PARTS: Wire (coat hanger is suitable)

PRELIMINARY PROCEDURE: Engine

NOTE

right side panels removed (page 9-14).

REMOVAL

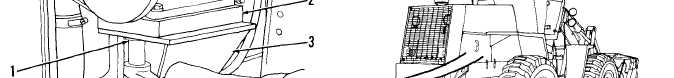

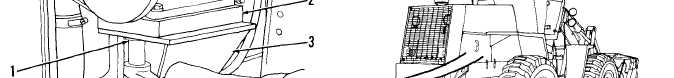

(a) Loosen two capscrews (1) securing air compressor (2) to mounting bracket

( 3 ).

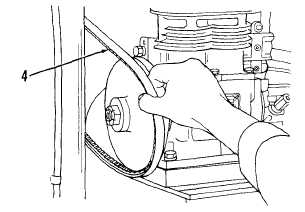

(b) Move air compressor closer to en-

gine then remove drive belt (4)

from air compressor pulley and

fan pulley.

INSTALLATION

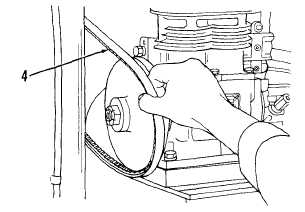

(a) Move air compressor close to en-

gine and position drive belt (4)

around fan pulley and air com-

p r e s s o r p u l l e y.

(b) Adjust tension of air compressor drive belt as described on page 7-97.

7-96