TM 5-3805-262-20

ADJUSTMENT

( a)

(b)

(c)

(d)

( e )

( f )

(g)

( h )

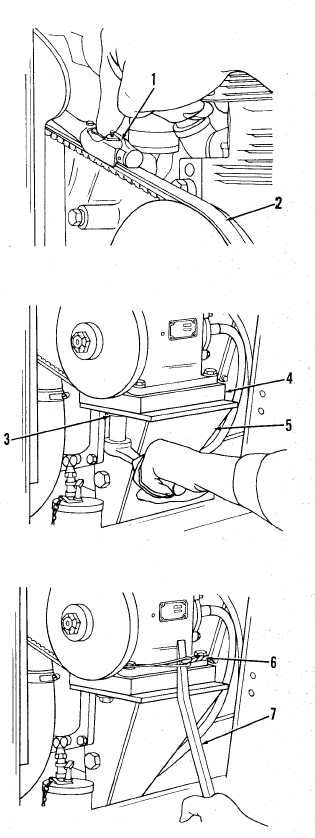

Using a belt tension gage (1),

check tension of drive belt (2)

as shown below. Tension of a

used drive belt shall be 90

pounds; tension of a new drive

belt shall be 110 pounds. If a

drive belt tension gage is not

a v a i l a b l e , d e p r e s s d r i v e b e lt

midway between air compressor

pulley and fan pulley. Drive

belt deflection should be 1/2

i n c h.

If tension of drive belt is not

as specified above, do the fol-

lowing steps.

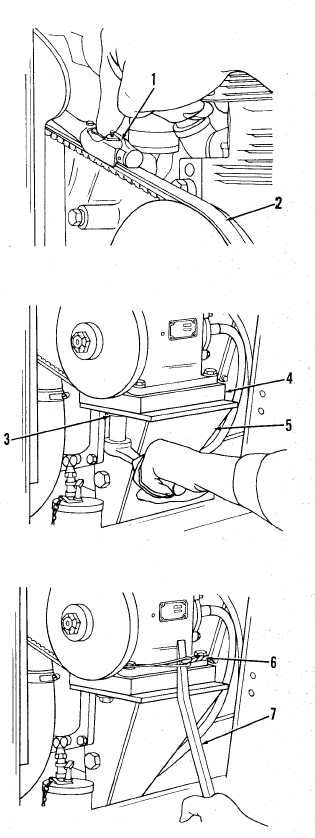

Loosen two capscrews (3) secur-

ing air compressor (4) to mount-

ing bracket (5).

Using clothes hanger wire, wrap

wire (6) around base of air com-

pressor as shown. Then, using a

prybar (7) move air compressor

away from engine until proper

d r i v e b e l t t e n s i o n i s o b t a i n e d.

Aline air compressor pulley with

fan pulley and tighten two cap-

screws (3) to secure air com-

pressor (4) to mounting bracket

( 5 ) .

Using belt tension gage (l),

check tension of drive belt (2)

as shown above. Tension of a

used drive belt shall be 90

pounds; tension of a new drive

belt shall be 110 pounds. If a

drive belt tension gage is not

a v a i l a b l e , d e p r e s s d r i v e b e lt

midway between air compressor

pulley and fan pulley. Drive

belt deflection should be 1/2

inch. If necessary, do steps (c)

through (e) above.

Remove wire from around base of

air compressor.

R e i n s t a l l e n g i n e r i g h t s i de

panels (page 9-17).

7-97