TM 5-3805-262-34

INSPECTION AND REPAIR ( SHEET 3 OF 3)

(7)

Check thickness of thrust washer (8) using micrometer. If thickness is

less than 0.1215 inch, replace thrust washer (8).

(8)

Using a micrometer, measure outside diameter of idler gear shaft. Replace

if outside diameter is less than 1.7325 inches.

(9)

Using a micrometer, measure thickness of idler gear thrust washer. Re-

place if thickness is less than 0.061 inch.

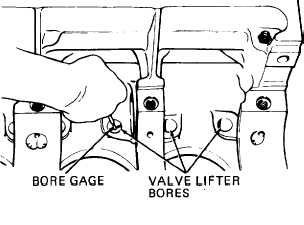

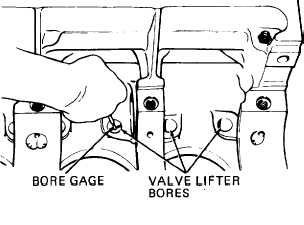

(10) Using bore gage and micrometer, measure inside diameter of idler gear.

Replace if inside diameter is more than 1.7375 inches.

(11) Using bore gage and micrometer,

measure diameter of valve lifter

bores in cylinder block. If di-

ameter of bores is more than

0.8135 inch at any point, bores

must be machined to 0.8220

0.0005 inch and over size lift-

ers must be used. If diameter of

any lifter bore is more than

0.8240 inch at any point, cylin-

der block must be replaced.

NOTE

When machining valve lifter bores, be sure that bores are 90 degrees to

camshaft bore centerline within a total tolerance of 0.001 per inch.

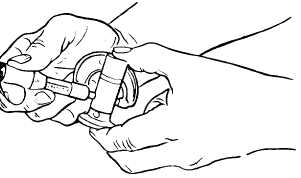

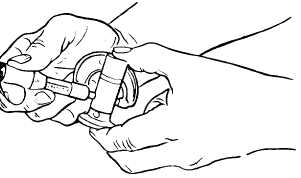

(12) Using micrometer, measure outside

diameter of valve lifter (13)

stem. Replace valve lifters if

outside diameter of lifter stem

is less than 0.8097 inch on

standard size valve lifters or

0.8190 inch on oversize valve

lifters.

NOTE

Replace an item if inspection indicates need for replacement.

(13) Inspect gears (5 and 6) for broken or missing teeth, distortion, cracks,

or pitting.

(14) Inspect camshaft (9) for damage or scoring.

(15) Inspect thrust spring (2) for distortion, cracks, or signs of permanent

set.

(16) Inspect nut (3) for thread damage or cracks.

4-61