TM 5-3805-262-34

4-6. CHASSIS SPINDLE ASSEMBLY MAINTENANCE (CONT)

REMOVAL (SHEET 2 OF 2)

e.

f.

g.

h.

i.

j.

k.

l.

m.

n.

Remove 6 capscrews (1) and lock washers (2) from upper chassis spindle (3).

Install two capscrews in threaded puller holes in spindle (3). Tighten cap-

screws evenly to pull spindle (3) from rear chassis.

Remove spindle (3), thrust bearing (4), and O-ring (5). Discard O-ring.

Remove lubrication fitting (7) from upper thrust plate cap (8).

Loosen and remove five capscrews (1) and lock washers (2) from upper thrust

plate cap (8).

Hold upper thrust plate cap (8) in position and remove remaining capscrew (1)

and lock washer (2).

Remove upper thrust plate cap (8) and, if present, shims (9 thru 11). Wire

shims together and identify to prevent mixing them with shims from lower

thrust plate cap.

NOTE

Do not perform steps 1 through n below unless inspection indicates parts

replacement is necessary.

Spindle bores in front and rear chassis must be alined to perform steps

l and m below.

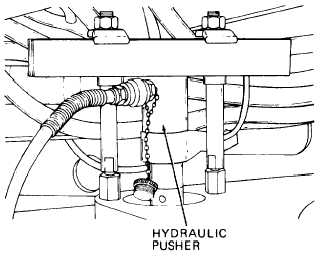

Install suitable hydraulic pusher on

top of rear chassis and push thrust

bearing (6) from bushing (12) using

3-7/8 inches diameter sleeve or rod.

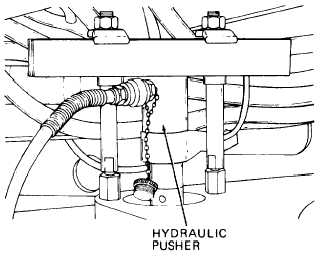

Using 4-1/4 inches outside diameter

sleeve or rod and hydraulic pusher,

push bushing (12) from front

chassis.

Using puller, remove thrust bearing

(4) from spindle (3).

NOTE

Repeat steps e through n above

to remove lower chassis spindle

parts.

4-252