TM 5-3805-262-34

INSPECTION/REPAIR (SHEET 4 OF 6)

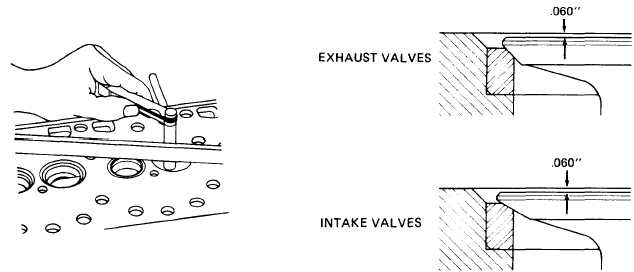

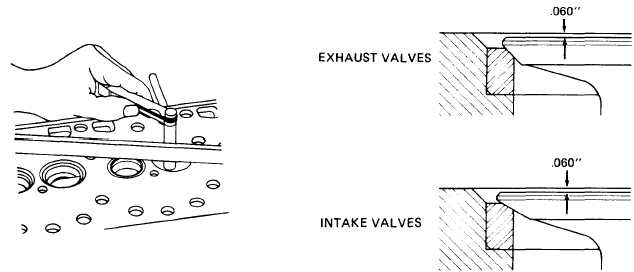

(7) Position each valve (6 and 9) in mating cylinder head bore and measure

valve head recession using straight edge and thickness gage. Replace

valve if recession exceeds 0.060 inch and check with new valve. If reces-

sion is greater than 0.060 inch with new valve, or if seat insert (7 or

10) is cracked or burned, replace seat insert as follows:

Temperature of solid carbon dioxide (dry ice) is below -70 degrees F.

Wear insulated gloves to prevent severe skin injury. If skin is injured

by contact with dry ice, flush with large amounts of cold water to raise

temperature above freezing point and obtain medical aid immediately.

(a) Pack new seat insert (7 or 10) in dry

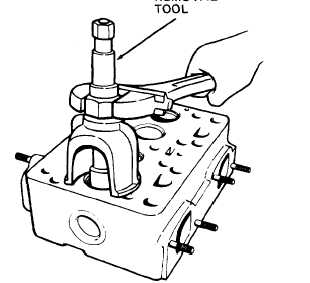

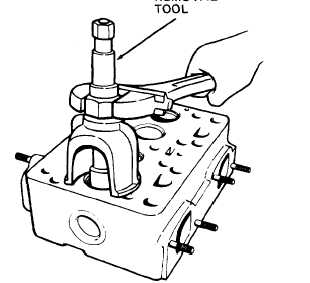

Do not use punch, chisel, or pry bar to

remove seat inserts (7 and 10). Use of

these or similar tools will damage cyl-

inder head.

(b) Pull seat insert (7 or 10) from cyl-

inder head using seat removal tool.

If tool is not available, remove

seat by machining out.

(c) Clean recessed area in cylinder

head.

(d) Press chilled seat insert (7 or 10)

into cylinder head until bottomed in

recess.

ice.

3-79