TM 5-3805-262-34

2-4. ENGINE TROUBLESHOOTING (CONT)

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

5. ENGINE NOISY (Cont).

Step 5. (Cont).

a. If crankshaft end play exceeds 0.015 inch, install oversize

thrust washers on both sides of number 5 main bearing cap (page

4-16) .

b. If crankshaft end play is not excessive, go to step 7 below.

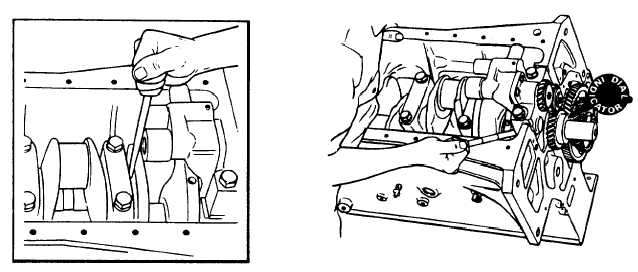

Step 6.

Tell assistant to start engine and operate at idle speed.

Listen for noise at cylinder block just below cylinder head and in

line with cylinder bore.

a. If no noise is heard, tell assistant to increase engine speed.

If noise gets louder as speed increases, remove valve springs

(page 3-74) and check using spring gage (page 3-76).

b. If noise is not heard at low or high engine speed go to step 7

below.

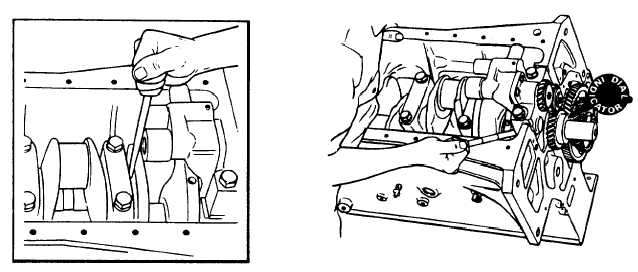

Step 7. Remove cylinder heads (page 3-45).

Check for foreign material in cylinders.

a. Remove foreign material.

Notify general support maintenance to remove pistons and rings

(page 4-42) and check for damage to pistons and rings (page

4-47) .

If engine was just overhauled, notify general support mainte-

nance to check piston rings for correct installation (page

4-49).

2-23