TM 5-3805-262-34

2-4. ENGINE TROUBLESHOOTING (CONT)

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

5. ENGINE NOISY (Cont).

Step 7. (Cont).

b. Check cylinder sleeves for ridge (page 4-43). If ridge is pre-

sent, remove (page 4-43).

c. If foreign material is not seen in cylinders, go to step 8 be-

low.

Step 8. Crank engine until piston is at top dead center.

Measure height of piston between top of piston to top of cylinder

sleeve. Repeat for remaining pistons.

a. A difference of 0.020 inch will indicate a bent connecting rod.

Notify general support maintenance to replace bent connecting

rods (page 4-42).

b.

If connecting rods are okay, go to step 9 below.

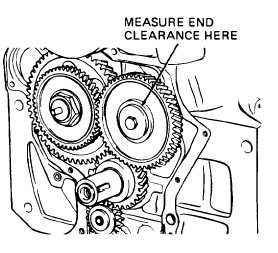

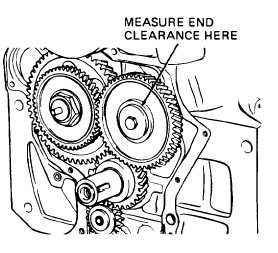

Step 9.

Remove timing gear cover (page

4-67) .

Check end clearance of idler

gear. Measure between thrust

plate and idler gear as shown.

End clearance should be not more

than 0.010 inch.

a. If end clearance is more than

0.010 inch, replace thrust wa-

sher, thrust plate, or idler

gear in any combination of

parts necessary to obtain

0.010 inch or less end clear-

ance.

b. If end clearance is 0.010 inch or less, check for broken or

missing thrust spring (page 4-55). Replace as necessary.

c. If all above parts are okay, check for a loose camshaft gear or

worn camshaft thrust washer (page 4-61).

2-24