TM 5-3805-262-34

INSTALLATION (SHEET 2 OF 2)

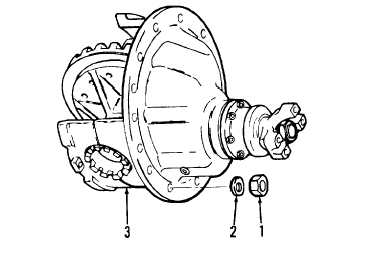

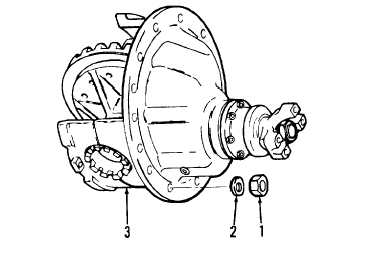

(5) Connect chain hoist to differential assembly (3).

(6) Put differential assembly (3) on roller jack and roll into position be-

neath front chassis. Raise roller jack to aline differential assembly

with its bore in axle housing.

(7) Guide differential assembly (3) to aline studs in housing with mating

holes in differential assembly.

(8) Install 14 washers (2) and nuts (l). Tighten nuts (1) to 110 to 165

lb-ft.

(9) Install axle shafts and planetary gear spiders (page 3-380).

(10) Install brake system lines and fittings (refer to TM 5-3805-262-20).

Whenever a component or line in the brake system is disconnected for

servicing, the air must be bled from the brake system. Failure to do so

could cause serious injury or death due to loss of braking control.

Refer to TM 5-3805-262-20 for bleeding air from brake system.

(11) Bleed air from hydraulic brake system (refer to TM 5-3805-262-20).

(12) Install front drive shaft and front wheels (refer to TM 5-3805-262-20).

(13) Service front axle (refer to TM 5-3805-262-20 and LO 5-3805-262-12).

(14) Install transport/service link in operating position (refer to TM

5-3805-262-10).

Be sure transport/service link is disengaged before driving vehicle.

Failure to do so could cause serious injury or death due to loss of

steering control.

LEGEND

1. Nuts (14)

2. Washers (14)

3. Differential assembly

3-365