TM 5-3805-262-34

INSPECTION (SHEET 1 OF 3)

NOTE

Over size pistons (18) and ring sets (13 thru 15) are available in 0.010

inch and 0.020 inch oversize. Oversize inserts (10) are also available

in 0.010 inch, 0.020 inch, and 0.030 inch oversize.

(a) Inspect cylinder block (2) for cracks and rough bores. If cracks are

seen, replace cylinder block. If bores are rough, hone bores to next

largest diameter listed below using cylinder wall hone and drill or

install new cylinder block.

Standard bore diameter

1.9995 to 2.0000 inches

0.010 inch oversize diameter

2.0095 to 2.0100 inches

0.020 inch oversize diameter

2.0195 to 2.0200 inches

NOTE

If cylinder block (2) bores are honed

to next oversize diameter, install

oversize pistons (18) and ring sets

(13 thru 15).

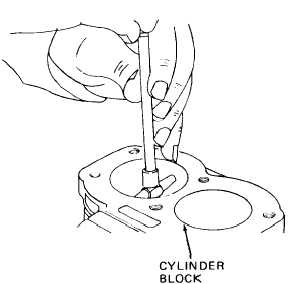

(b) Measure diameter of each bore in

cylinder block (2) near top of

each bore at a 90 degree angle to

wrist pin (17) using bore gage and

micrometer. Record measurement.

Then make three more measurements

down length of bores. If differ-

ence between any measurement is

more than 0.001 inch, there is too

much taper in bore. Increase diam-

eter of bore to next larger diam-

eter listed above or install new cylinder block.

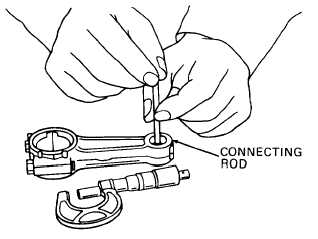

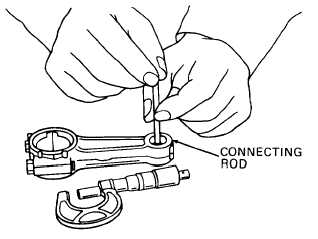

(c)

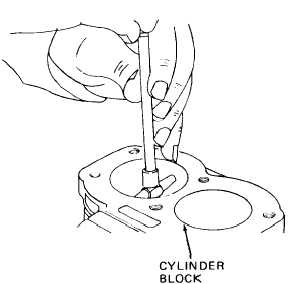

(d)

Measure diameter of each bore in cylinder block (2) near top of bore in

four different places using bore gage and micrometer. If difference

between any measurement is more than 0.005 inch, bore is out of round.

Increase diameter of bore to next larger diameter listed above or in-

stall a new cylinder block.

Measure diameter of wrist pin

bore in connecting rods (12)

using bore gage and microm-

eter. If measurement is more

than 0.5004 inch, a new con-

necting rod must be installed.

3-483